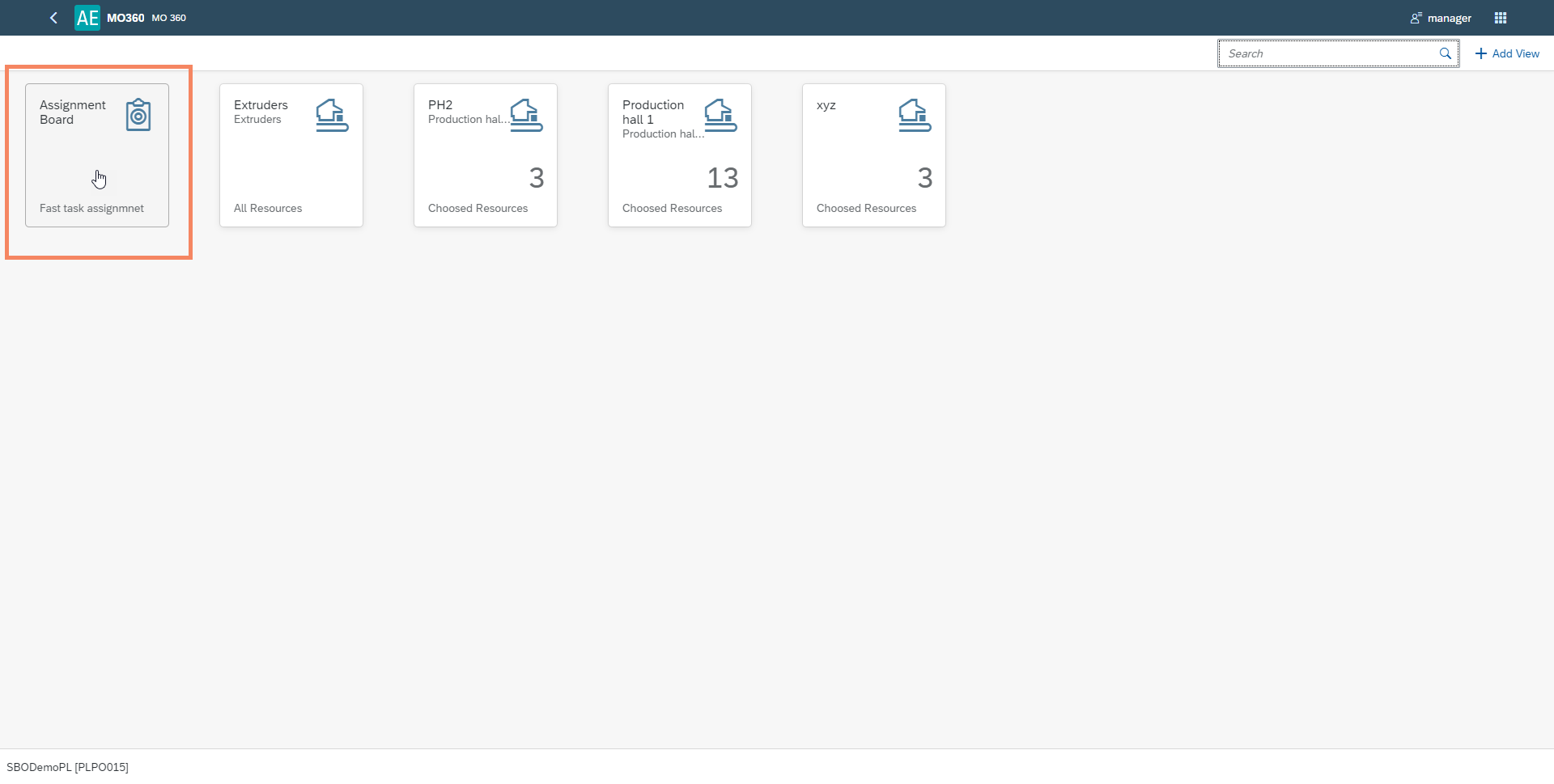

Assignment Board

This guide outlines key functionalities for scenario definition, team management, task allocation, and Manufacturing Order (MO) tracking, ensuring a seamless production workflow.

Assignment Board

Teams

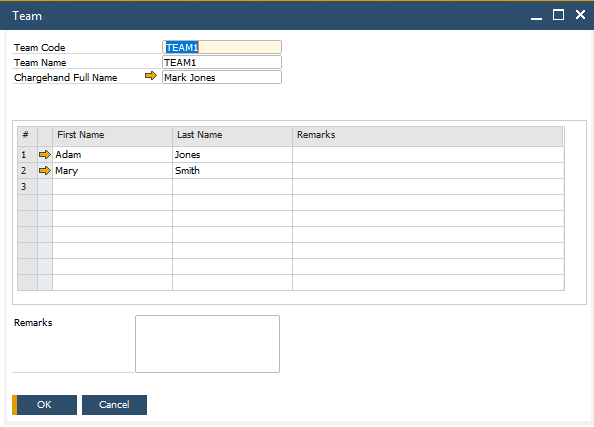

Production → Time Booking → Team

Define teams in SAP Business One to be visible on the Assignment Board:

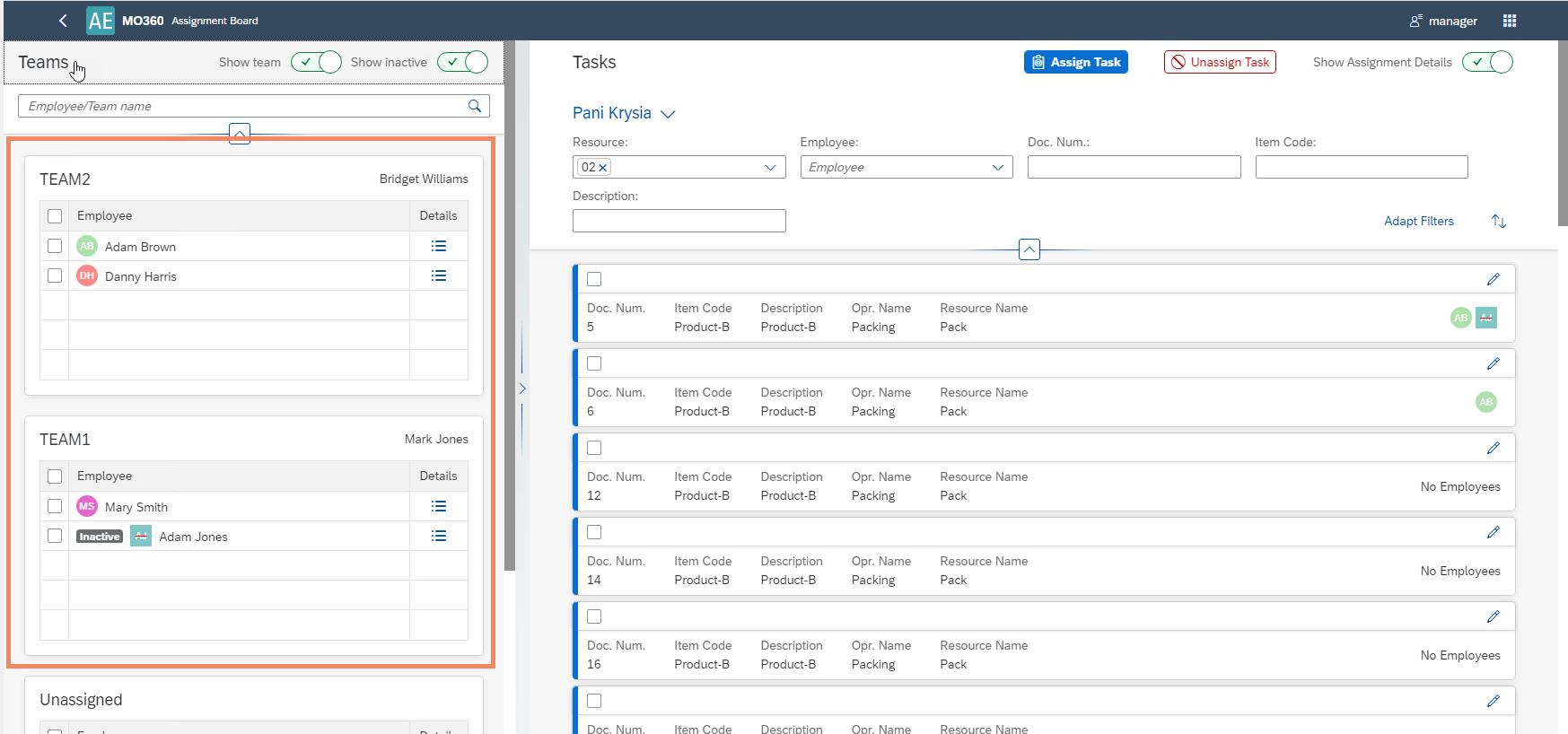

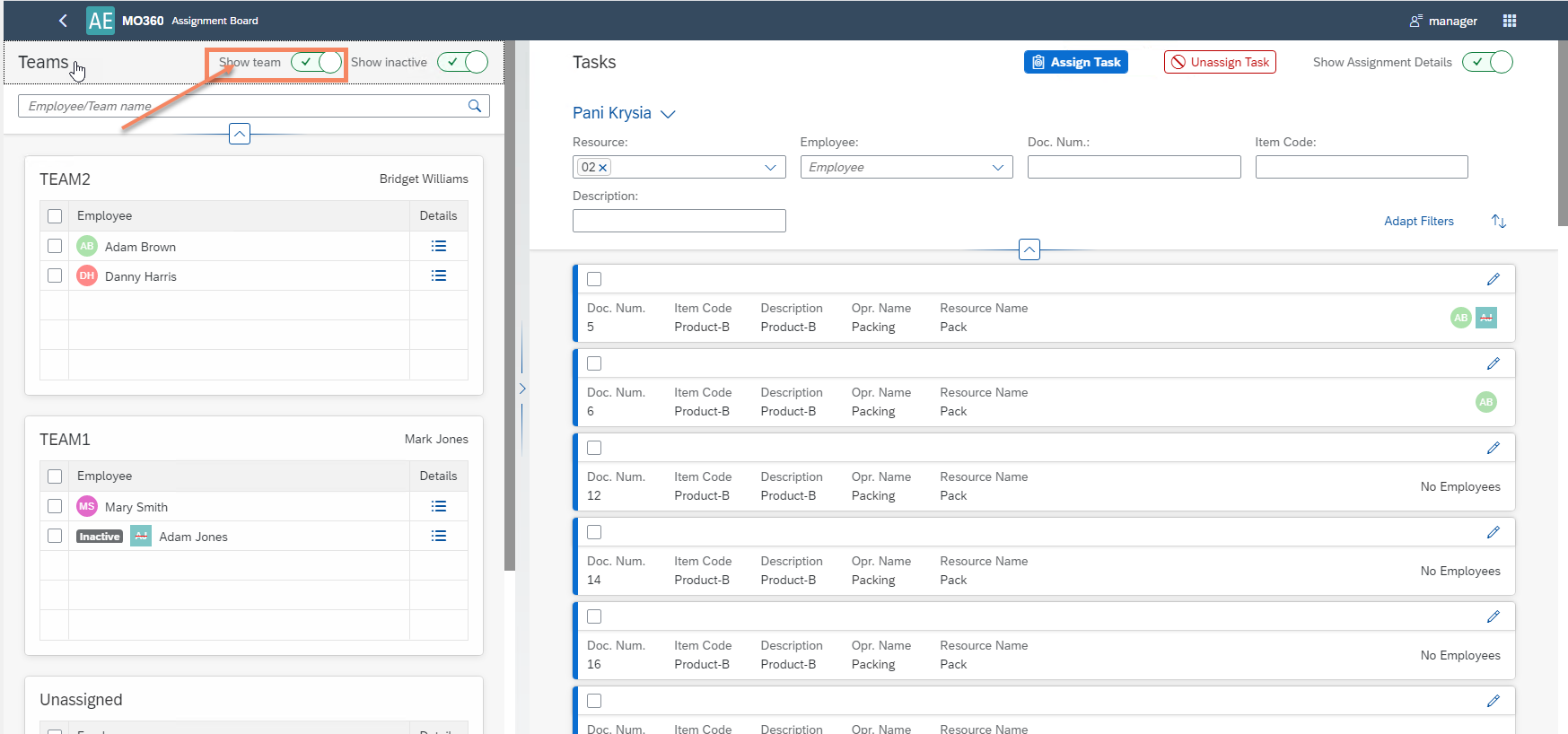

After opening the Assignment Board, the system will show all available Teams:

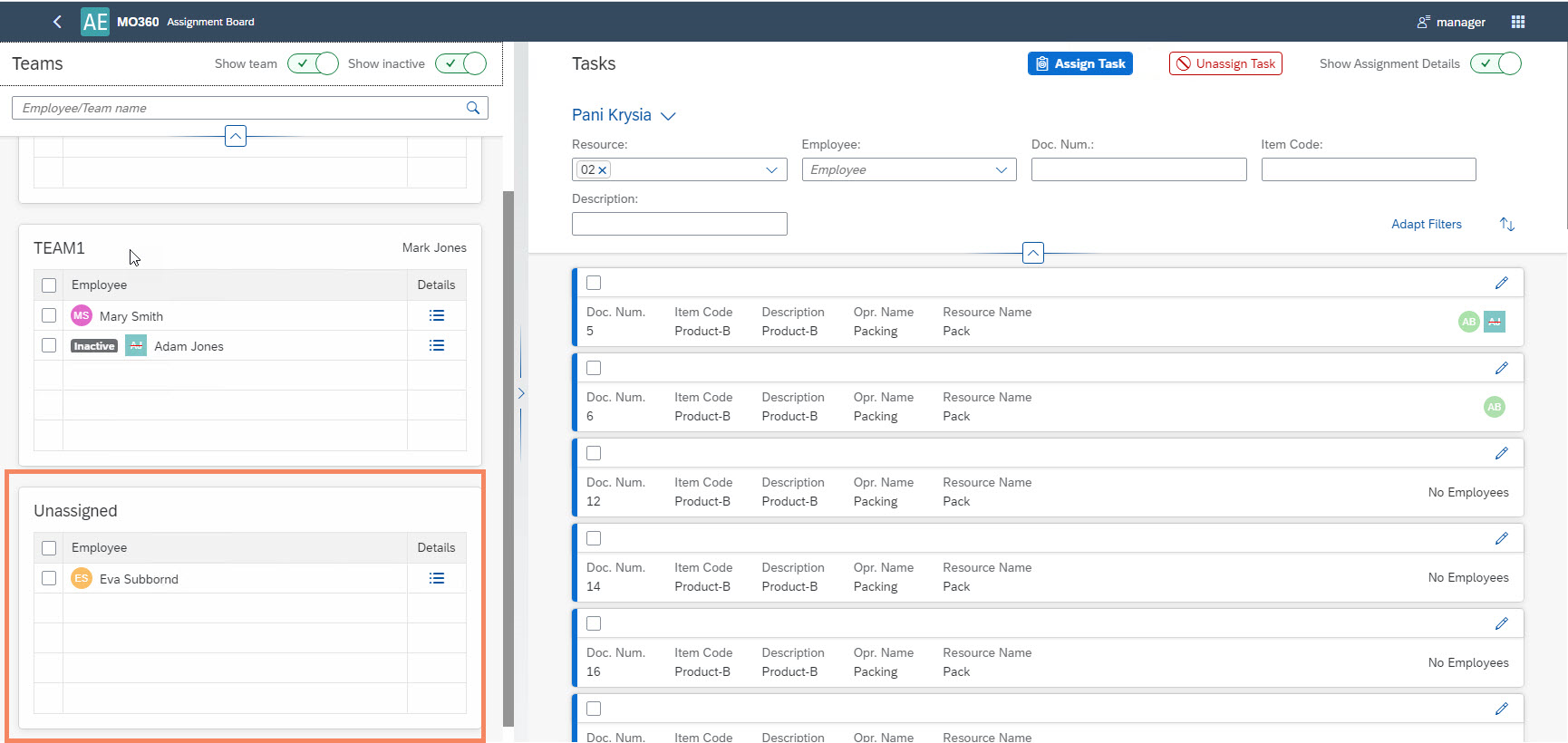

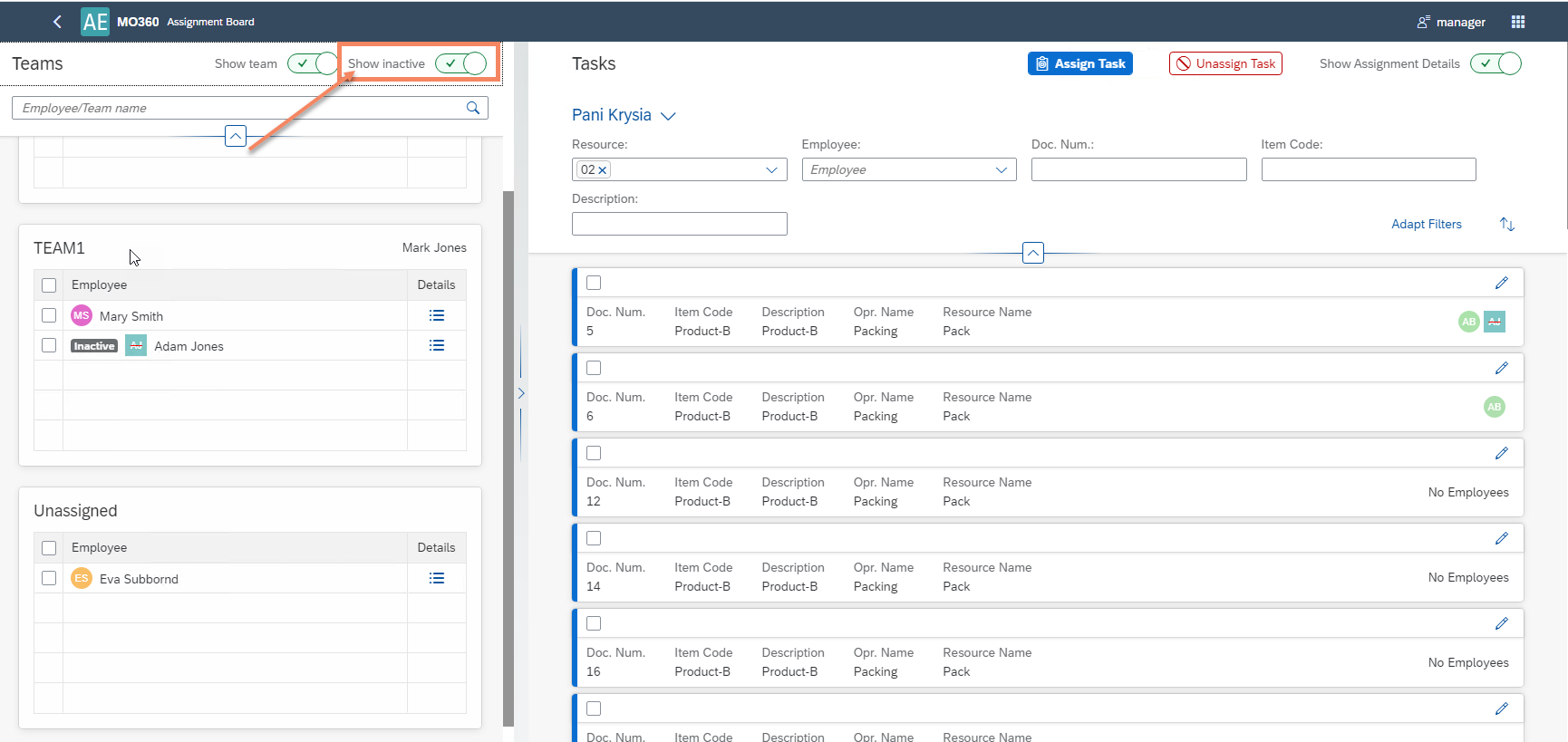

At the bottom, you can find unassigned employees:

You can also view all Employees (regardless of a Team they are assigned to). All you have to do is unselect 'Show team':

On the view, you can find all employees – active and inactive. If you wish to see only active, you can change the below setting:

Tasks

My Views

You can create a filter view template. It may differ depending on a group of employees.

Click here to know more about filtering tasks.

Assign a Task to Employees

You can select tasks manually or filter them with preconfigured filters. The list contains Manufacturing Orders that in Released or Started status. Manufacturing Orders are broken down into Operations and Resources. The list shows Machine, Tool and Subcontracting Resources. The list shows the same Tasks that can also be assigned from the CompuTec PDC level.

Click here to know more about assigning tasks.

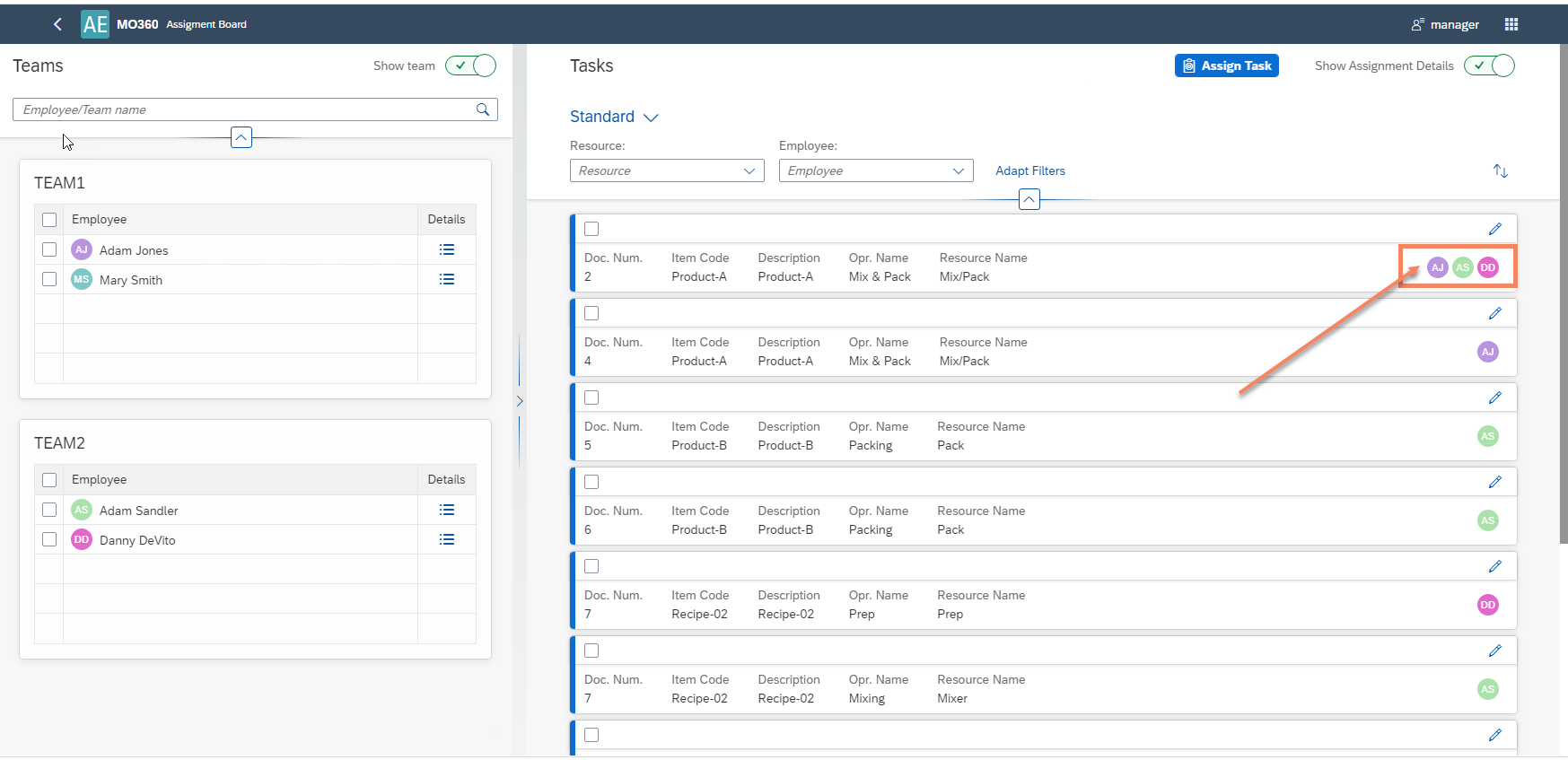

From the Team panel, you can choose one or more Employees or the entire Team.

Once the Employee/Employees are assigned, they are visible in the taskbar.

The effect of the assigning of a Task is the creation of a CompuTec PDC tile assigned to a specific Employee.

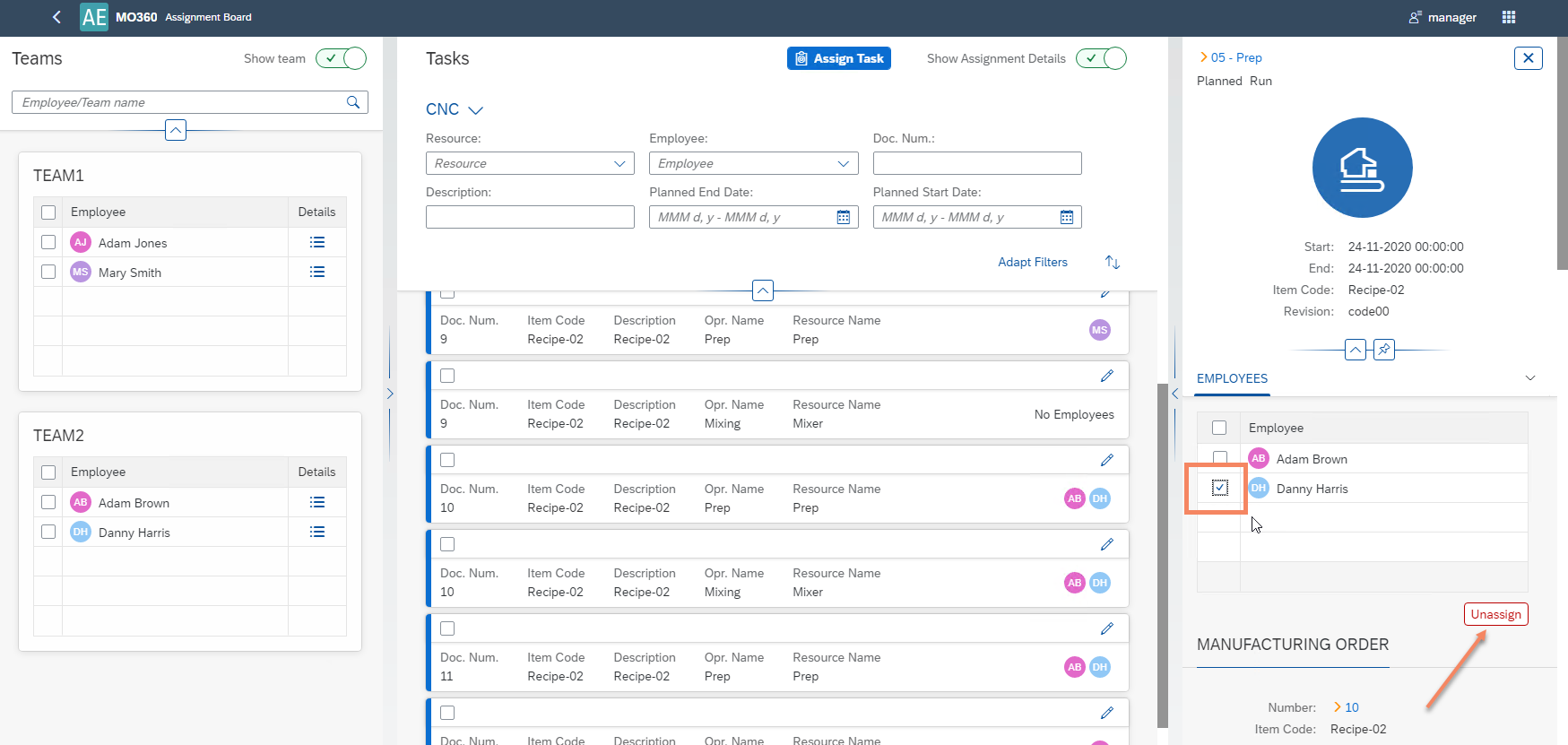

Unassigning Task from Employees

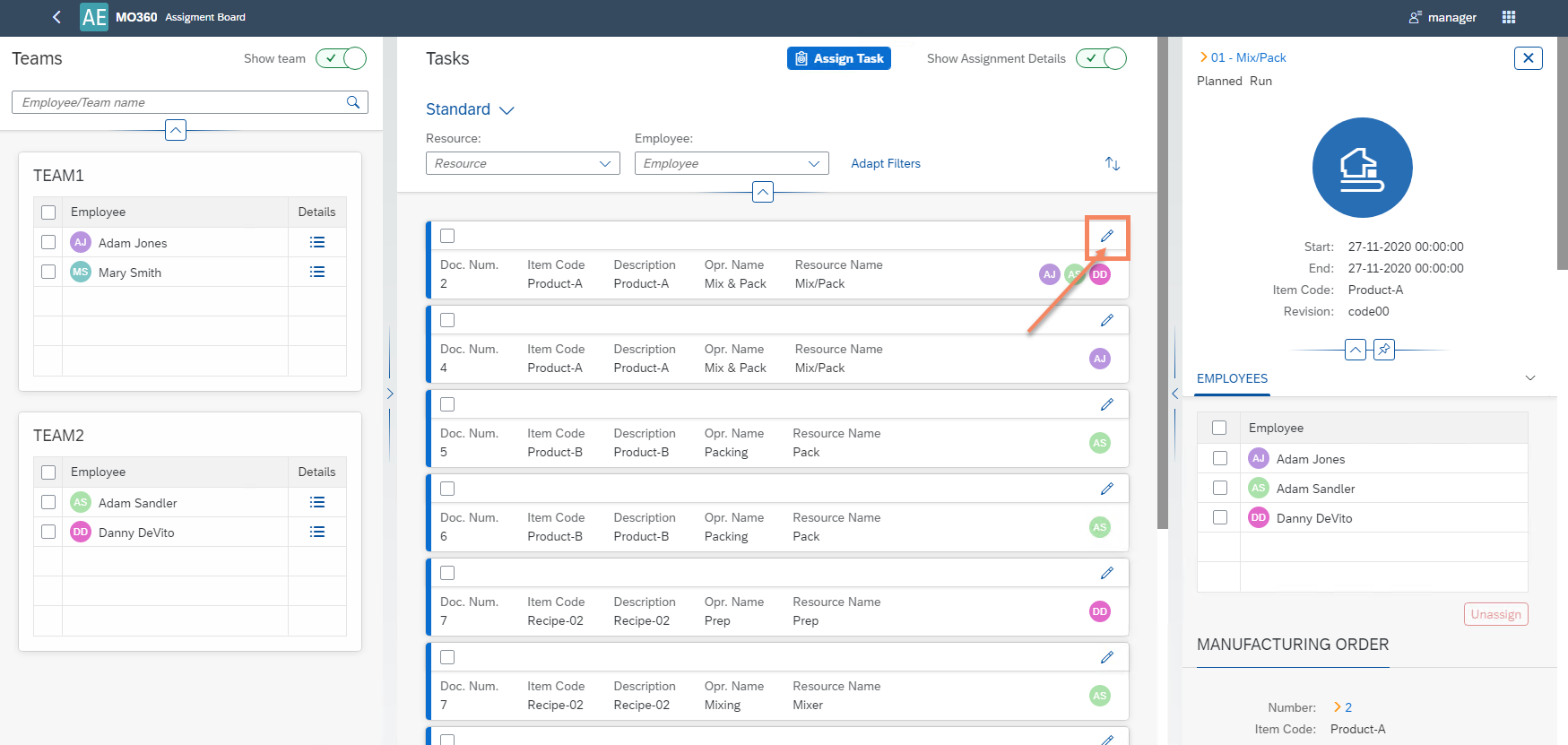

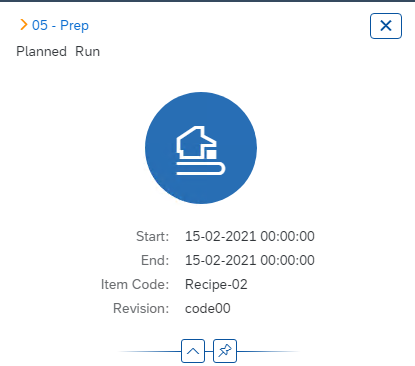

Changes to the assigned Task are made in the edit mode. After entering this mode, the side panel on the right side of the screen opens. We can verify the details of the Task as well as unassign from an Employee.

Next, select employees and unassign.

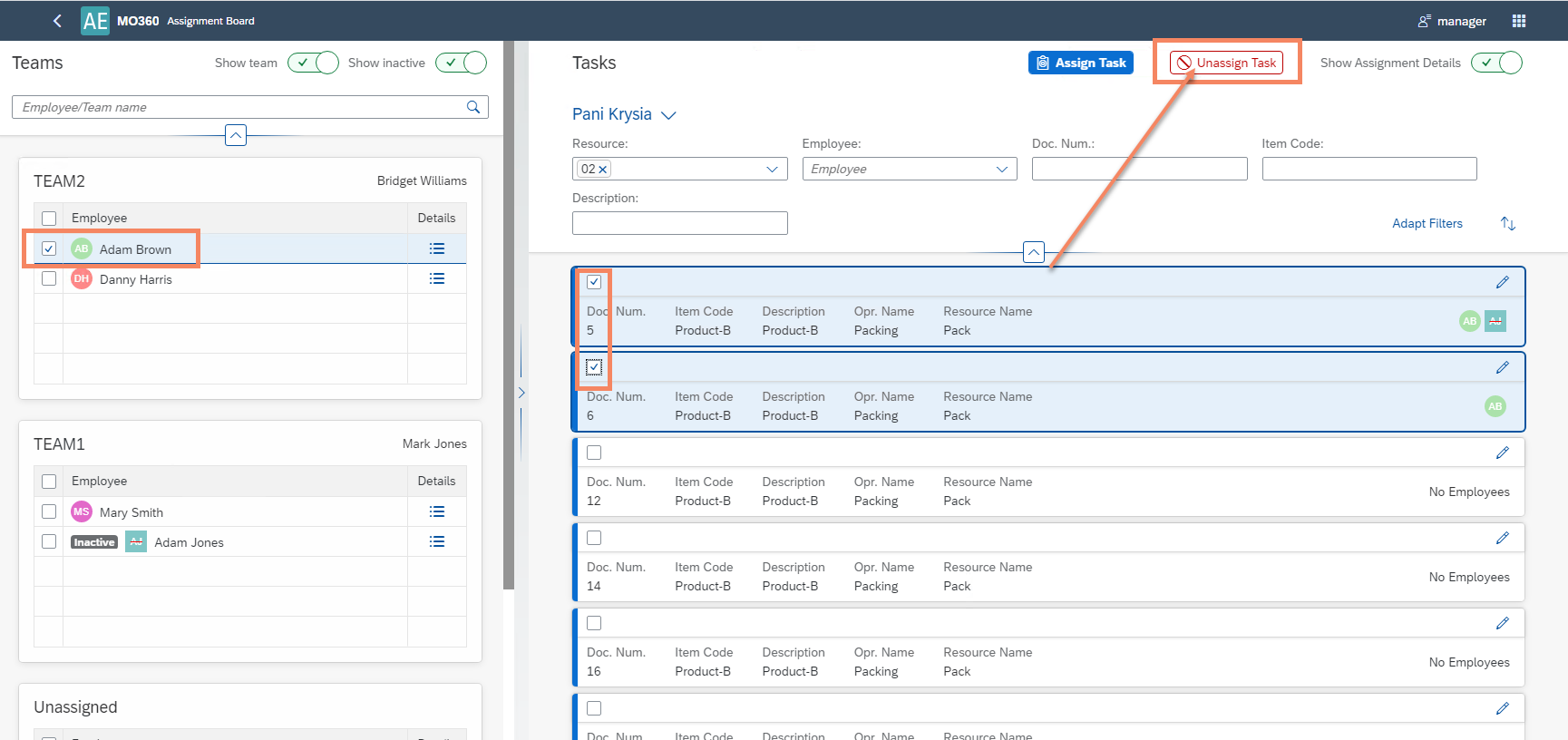

Another method to unassign an employee from the task is to check the employee(s) and then the task(s) and use the button at the top:

Manufacturing Order Details

In this section, you can find the following information about the Manufacturing Order:

-

Operation

-

Planned Start Date and End Date

-

Header Item Code and Revision

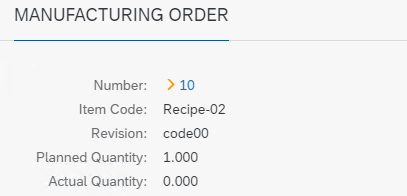

Manufacturing Order

-

Manufacturing Order details - Includes details such as Number, Item Code, Revision, Planned and Actual Quantity, Required Date

Operation

-

Operation details - Includes details such as Code, Name, Sequence, and Status

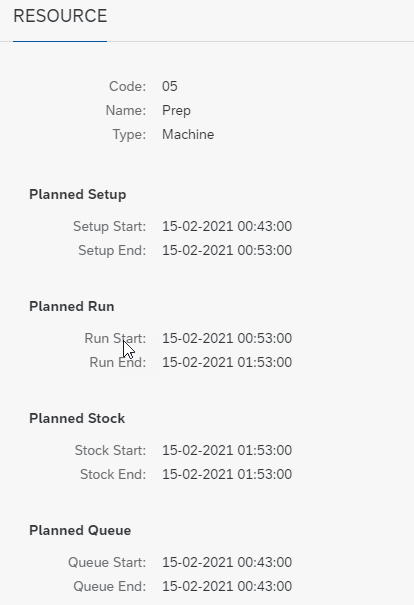

Resource

-

Resource details - Includes details such as code, name, and type.

-

Time details - Provides start and end times for all time categories.

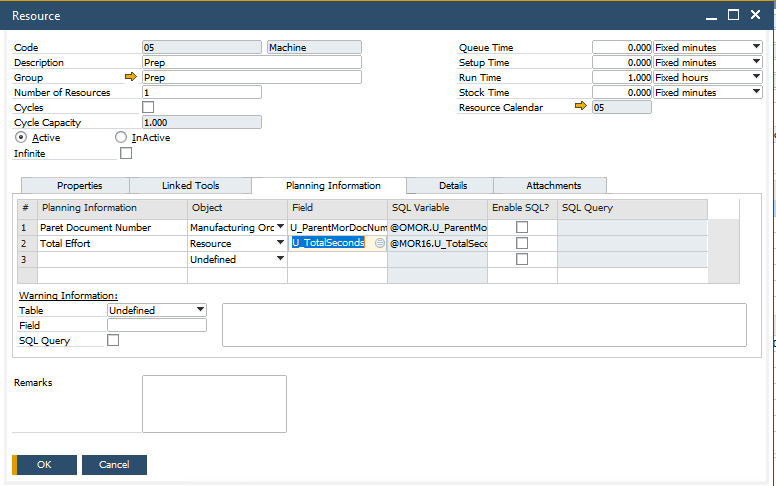

Additional information

-

Additional information from Resource:

By leveraging these tools, businesses can enhance resource utilization and improve overall operational efficiency.