You are currently viewing documentation for CompuTec ProcessForce 3.0, which is a plugin installed and managed through CompuTec AppEngine 3.0, built on .NET 8.

If you are working with older environments, you may need the documentation for CompuTec ProcessForce 2.0, which is still supported: https://learn.computec.one/docs/processforce/2.0/.

Please note that CompuTec AppEngine 3.0 introduces a new architecture. All CompuTec components, including the CompuTec ProcessForce 3.0 plugin, must be updated together to ensure full compatibility.

Before starting your installation or upgrade process, we strongly recommend reviewing the CompuTec AppEngine 3.0 and CompuTec ProcessForce 3.0 documentation.

Fixed Quantity Backflushing

Fixed Quantity Backflushing automates the consumption of materials in production, ensuring efficient inventory tracking and reducing manual effort. This method allows manufacturers to backflush a predetermined quantity of raw materials, regardless of the actual production output. By integrating Fixed Backflush into the Bill of Materials (BOM) and Manufacturing Order (MOR), businesses can enhance accuracy and efficiency in production reporting.

Bill of Material and Manufacturing Order

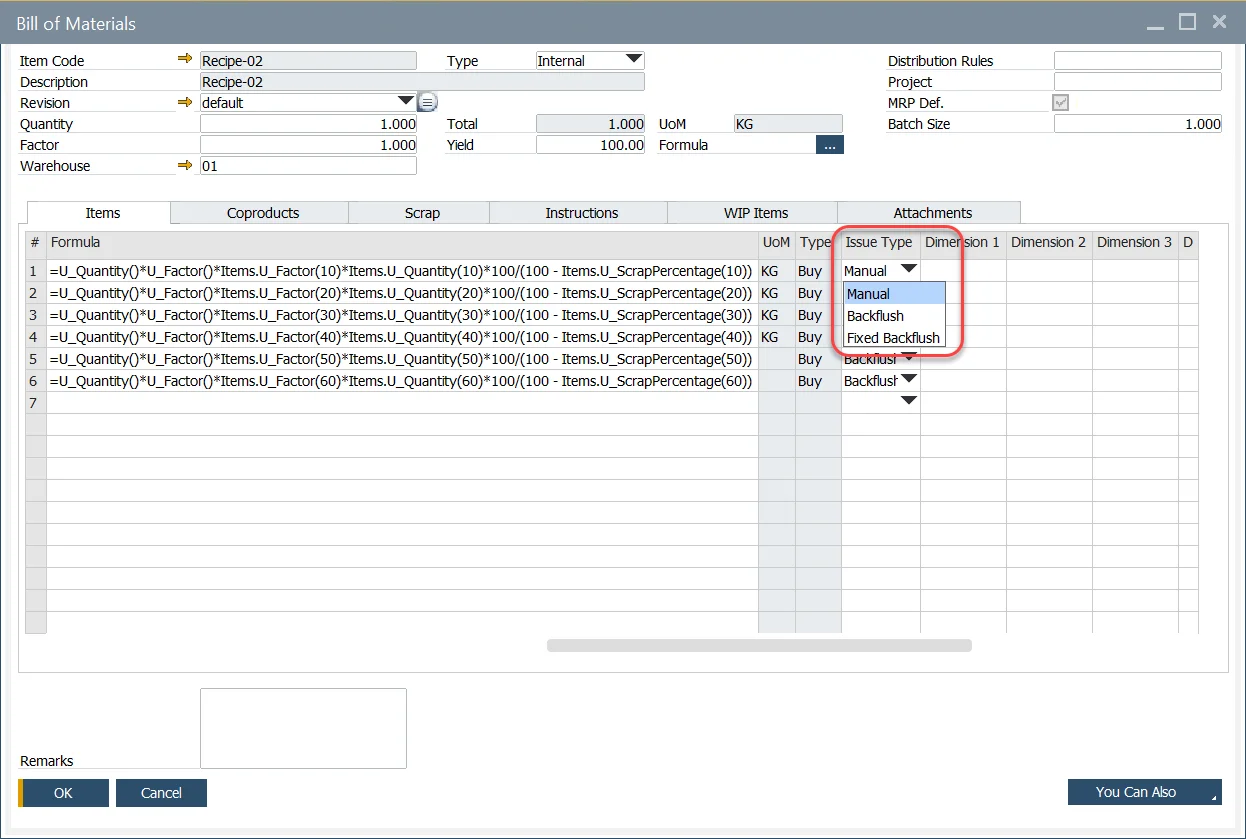

To backflush the total quantity of an Item based on a partial or a full quantity production receipt, select the "Fixed Backflush" option:

Pick Order – Receipt from Production

Based on the "Backflush Type," the amount to be posted are calculated based on the following rules:

| Item | BOM Quantity | Type | Method | Backflush Type | MOR Planned Quantity | Planned Quantity | Receipt | Actual Quantity |

|---|---|---|---|---|---|---|---|---|

| Product 1 = BOM | 1 | 100 | 10 | |||||

| Ingredient 1 | 0.9 | Backflush | Proportional Quantity | Backflush | 90 | 9 | ||

| Ingredient 2 | 0.02 | Backflush | Fixed Quantity | Fixed Backflush | 2 | 2 | ||

| Ingredient 3 | 0.08 | Manual | 8 |

Partial Receipt of 10:

| Item | BOM Quantity | Type | Method | Backflush Type | MOR Planned Quantity | Planned Quantity | Receipt | Actual Quantity |

|---|---|---|---|---|---|---|---|---|

| Product 1 = BOM | 1 | 100 | 10 | |||||

| Ingredient 1 | 0.9 | Backflush | Proportional Quantity | Backflush | 90 | 9 | ||

| Ingredient 2 | 0.02 | Backflush | Fixed Quantity | Fixed Backflush | 2 | 2 | ||

| Ingredient 3 | 0.08 | Manual | 8 | 0 | ||||

| CoProduct 1 | 0.1 | Backflushed | Proportional Quantity | Backflush | 10 | 1 | ||

| CoProduct 2 | 0.2 | Backflushed | Fixed Quantity | Fixed Backflush | 20 | 20 | ||

| CoProduct 3 | 0.3 | Manual | 30 | 0 | ||||

| Scrap 1 | 0.1 | Backflushed | Proportional Quantity | Backflush | 10 | 1 | ||

| Scrap 2 | 0.2 | Backflushed | Fixed Quantity | Fixed Backflush | 20 | 20 | ||

| Scrap 3 | 0.3 | Manual | 30 | 0 |

Balance of Receipt 90:

| Item | BOM Quantity | Type | Method | Backflush Type | MOR Planned Quantity | Planned Quantity | Receipt | Actual Quantity |

|---|---|---|---|---|---|---|---|---|

| Product 1 = BOM | 1 | 100 | 90 | |||||

| Ingredient 1 | 0.9 | Backflush | Proportional Quantity | Backflush | 90 | 81 | ||

| Ingredient 2 | 0.02 | Backflush | Fixed Quantity | Fixed Backflush | 2 | 0 | ||

| Ingredient 3 | 0.08 | Manual | 8 | 0 | ||||

| CoProduct 1 | 0.1 | Backflushed | Proportional Quantity | Backflush | 10 | 9 | ||

| CoProduct 2 | 0.2 | Backflushed | Fixed Quantity | Fixed Backflush | 20 | 0 | ||

| CoProduct 3 | 0.3 | Manual | 30 | 0 | ||||

| Scrap 1 | 0.1 | Backflushed | Proportional Quantity | Backflush | 10 | 9 | ||

| Scrap 2 | 0.2 | Backflushed | Fixed Quantity | Fixed Backflush | 20 | 0 | ||

| Scrap 3 | 0.3 | Manual | 30 | 0 |

Over Receipt of 10:

| Item | BOM Quantity | Type | Method | Backflush Type | MOR Planned Quantity | Planned Quantity | Receipt | Actual Quantity |

|---|---|---|---|---|---|---|---|---|

| Product 1 = BOM | 1 | 100 | 10 | |||||

| Ingredient 1 | 0.9 | Backflush | Proportional Quantity | Backflush | 90 | 9 | ||

| Ingredient 2 | 0.02 | Backflush | Fixed Quantity | Fixed Backflush | 2 | 0 | ||

| Ingredient 3 | 0.08 | Manual | 8 | 0 | ||||

| CoProduct 1 | 0.1 | Backflushed | Proportional Quantity | Backflush | 10 | 1 | ||

| CoProduct 2 | 0.2 | Backflushed | Fixed Quantity | Fixed Backflush | 20 | 0 | ||

| CoProduct 3 | 0.3 | Manual | 30 | 0 | ||||

| Scrap 1 | 0.1 | Backflushed | Proportional Quantity | Backflush | 10 | 1 | ||

| Scrap 2 | 0.2 | Backflushed | Fixed Quantity | Fixed Backflush | 20 | 0 | ||

| Scrap 3 | 0.3 | Manual | 30 | 0 |