You are currently viewing documentation for CompuTec ProcessForce 3.0, which is a plugin installed and managed through CompuTec AppEngine 3.0, built on .NET 8.

If you are working with older environments, you may need the documentation for CompuTec ProcessForce 2.0, which is still supported: https://learn.computec.one/docs/processforce/2.0/.

Please note that CompuTec AppEngine 3.0 introduces a new architecture. All CompuTec components, including the CompuTec ProcessForce 3.0 plugin, must be updated together to ensure full compatibility.

Before starting your installation or upgrade process, we strongly recommend reviewing the CompuTec AppEngine 3.0 and CompuTec ProcessForce 3.0 documentation.

Resource Balancing

Resource Balancing allows the system to automatically select the most optimal resource for a specific task within a Manufacturing Order (MO).

It improves scheduling efficiency by evaluating parameters such as:

- Operation quantity

- Resource availability

- Calendar schedules

- Operation run times

Rather than relying on a default resource, the system calculates which resource can complete the work in the shortest possible time.

This feature applies to resources defined in:

- Production Process

- Manufacturing Order

- Alternative Resources

It is strongly recommended to test this option in a non-production environment before enabling it in a live system.

How-to Guide

Resource Balancing allows you to select the most suitable resource for a task in a Manufacturing Order by evaluating multiple factors like operation quantities, related times, resource availability, and resource calendars. Instead of relying on a default resource, the system calculates the optimal resource that can complete the work in the least amount of time.

Below is an example that illustrates how the system selects the most efficient resource based on predefined parameters such as run time and availability.

- Quantity on Manufacturing Order: 100 pcs

- Scheduling Direction: Forward (from date 01/01)

- All machines are available 24/7

| Resource | Run Rate | Run Time | Available From | Finish Time |

|---|---|---|---|---|

| M1 | 10 pcs/h | 10 hours | 10.01 10:00 AM | 10.01 08:00 PM |

| M2 | 10 pcs/h | 10 hours | 11.01 05:00 PM | 12.01 03:00 AM |

| M3 | 5 pcs/h | 20 hours | 09.01 01:00 AM | 09.01 09:00 PM |

| M4 | 5 pcs/h | 20 hours | 10.01 05:00 AM | 10.01 01:00 AM |

| M5 | 10 pcs/h | 10 hours | 10.01 07:00 PM | 11.01 05:00 AM |

Note: The system will choose M3 for this work

Prerequisites

Run Time

Resource Balancing depends on valid Run Time values for machine-type resources.

Make sure all such resources have Run Time > 0.

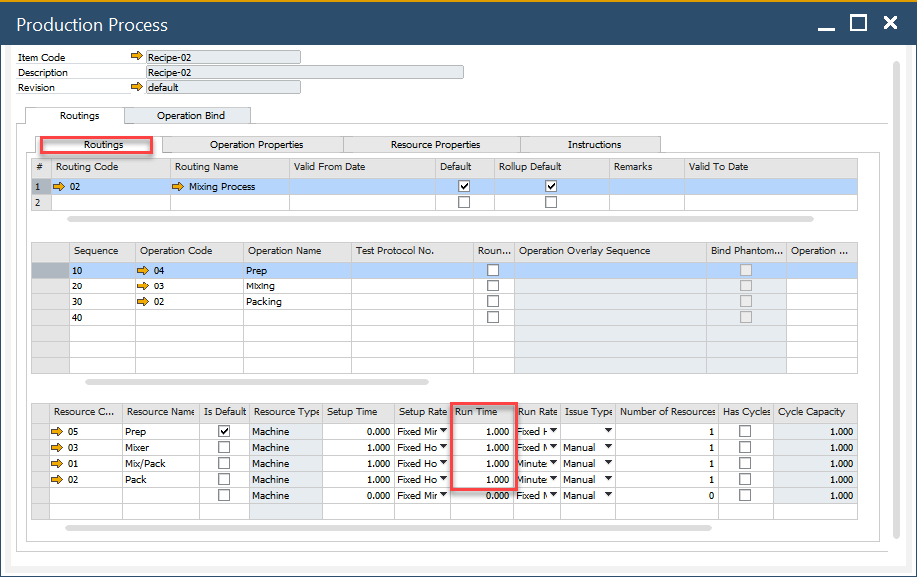

1. In the Production Process

-

Open the Production Process form.

-

Check that each machine-type resource in the operations list has a Run Time greater than zero.

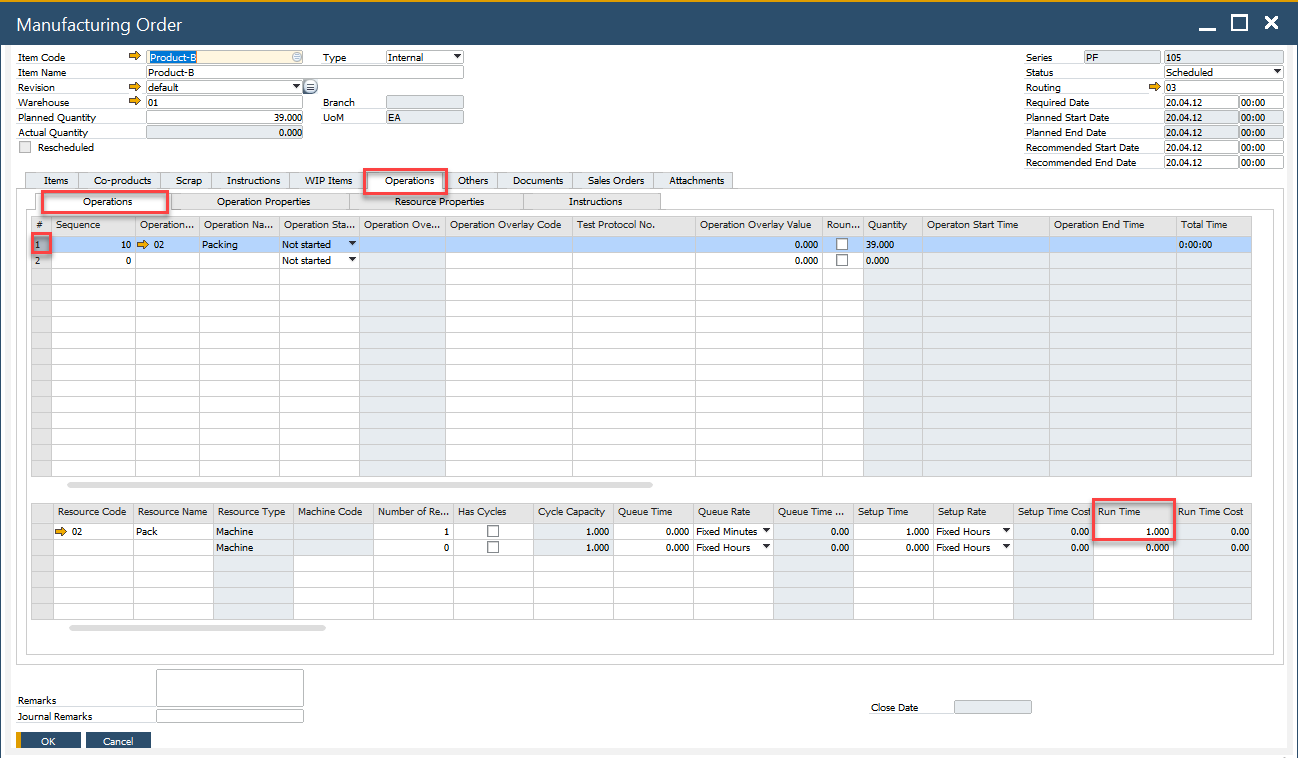

2. In the Manufacturing Order

-

Open the Manufacturing Order.

-

Review the operations tab.

-

Verify that each machine-type resource has a Run Time greater than zero.

General Settings Options

To activate Resource Balancing, navigate to:

Administration → System Initialization → General Settings → ProcessForce tab → Bill of Materials and Manufacturing Orders

Check the "Use Resource Balancing" check box to use the option.

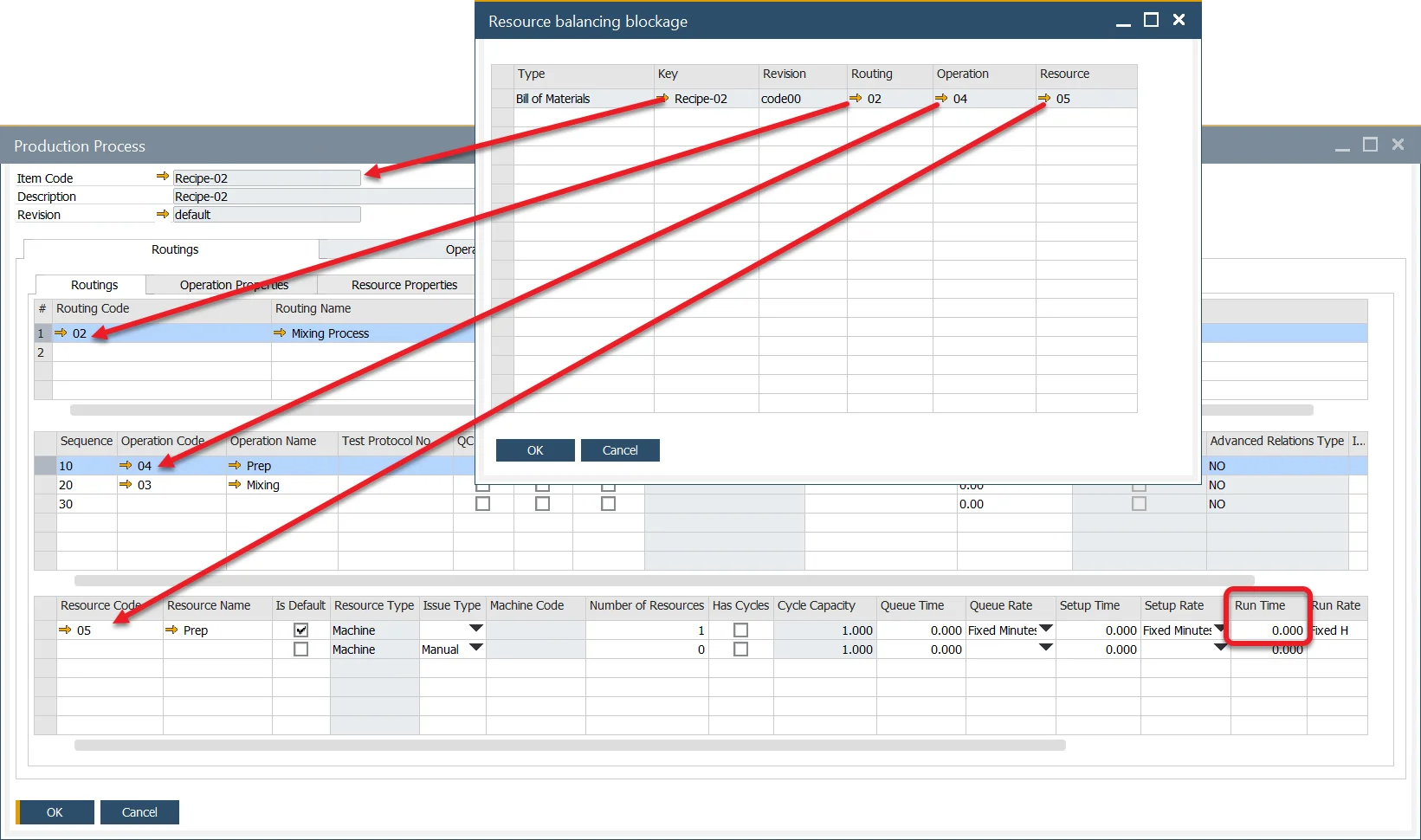

Resource Balancing Blockage

If any machine-type resource has a Run Time = 0, the system will block the activation and show a Resource Balancing Blockage form.

- This form lists all problematic resources.

- Update their Run Time values to continue.

Usage

Once enabled, the system automatically executes Resource Balancing when you:

- Open the Scheduling Board / Semi-finished Product Scheduling form

- Change the Planned Quantity or Header Dates in the Manufacturing OrderChanging the Planned Quantity or Manufacturing Order header dates

The system re-evaluates the best available resource dynamically, ensuring optimized scheduling.

Log files

You can activate a log feature to track all actions related to Resource Balancing, which includes detailed data on every scheduling and rescheduling action.

Enabling detailed logs may impact system performance.

To activate the option, perform the following steps:

-

Navigate to: C:\Program Files\sap\SAP Business One\AddOns\CT\ProcessForce.

-

Open the ProcessForce.exe.config file with a text editor.

-

Change the value from "false" to "true" in the following line:

<add key="SchedulingBalancingEnabled" value="false" />After enabling the feature, log files will be saved in the default directory:

C:\ProgramData\CompuTec\ProcessForce\ResourceBalancing.A separate file is saved for changes made for each Operation.

Why Use Resource Balancing?

| Benefit | Description |

|---|---|

| Efficiency | Automatically picks the fastest-available resource. |

| Reduced Manual Planning | No need to manually assign resources per operation. |

| Improved Throughput | Makes full use of available capacity across machines. |

| Real-Time Adjustments | Dynamically reacts to date or quantity changes. |

When Not to Use

Avoid enabling Resource Balancing if:

- Resources lack proper calendars or run times.

- Scheduling decisions must remain under manual control.

- You are in a production environment without prior testing.

⚠️ Recommendation: Always test in a staging or sandbox environment before applying to live systems.