You are currently viewing documentation for CompuTec ProcessForce 3.0, which is a plugin installed and managed through CompuTec AppEngine 3.0, built on .NET 8.

If you are working with older environments, you may need the documentation for CompuTec ProcessForce 2.0, which is still supported: https://learn.computec.one/docs/processforce/2.0/.

Please note that CompuTec AppEngine 3.0 introduces a new architecture. All CompuTec components, including the CompuTec ProcessForce 3.0 plugin, must be updated together to ensure full compatibility.

Before starting your installation or upgrade process, we strongly recommend reviewing the CompuTec AppEngine 3.0 and CompuTec ProcessForce 3.0 documentation.

Scheduling Board

Scheduling Board is a production planning tool that allows scheduling (and rescheduling) several Manufacturing Orders (filtered by chosen criteria) quickly. It also allows managing Manufacturing Orders based on a multi-level Bill of Materials, considering the product structure. Due to the usage of product planning-relate-dated dates and times, the system can communicate situations when it is impossible to process a Manufacturing Order on time for the planned Delivery Date and suggest the first date available to do this.

How to Open Scheduling Board / Semi-finished Product Scheduling

The Scheduling Board can be accessed from the following areas in the system:

Scheduling

Production → Manufacturing Order → Scheduling

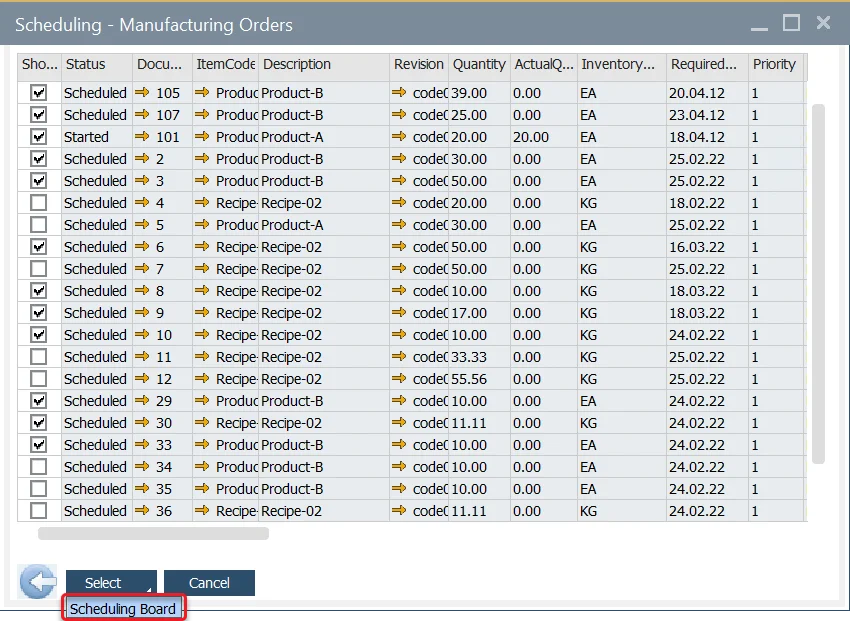

Here, you can select a single Manufacturing Order or multiple orders as needed.

-

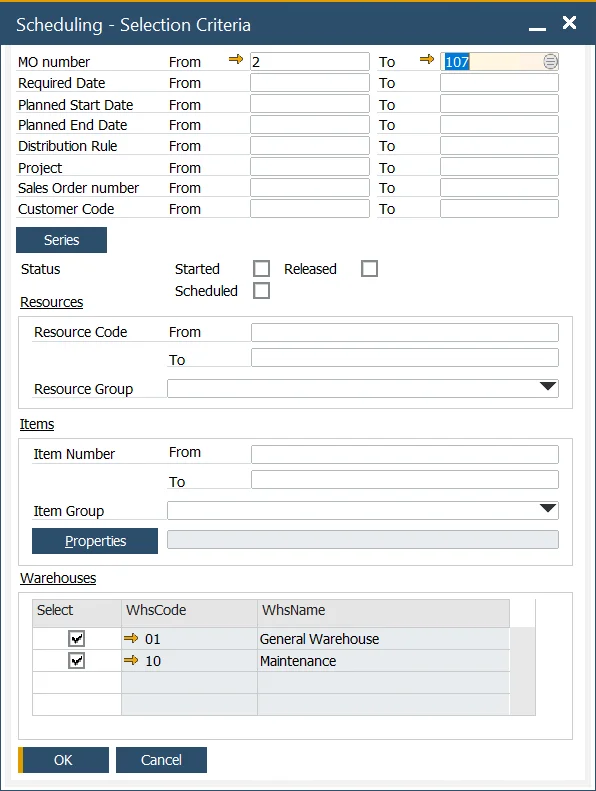

You can select/deselect all the Warehouses by double-clicking on the top of the Select column.

-

To select or deselect all Warehouses, double-click the top of the Select column.

-

Use the Scheduling Selection Criteria to filter the Manufacturing Orders you want to display. After setting the criteria, click OK. If no criteria are specified, all Manufacturing Orders in the system are displayed by default.

-

A list of selected Manufacturing Orders will appear. To proceed, click on the Select button and choose the Scheduling Board option:

Sales Order

Sales A/R → Sales Order

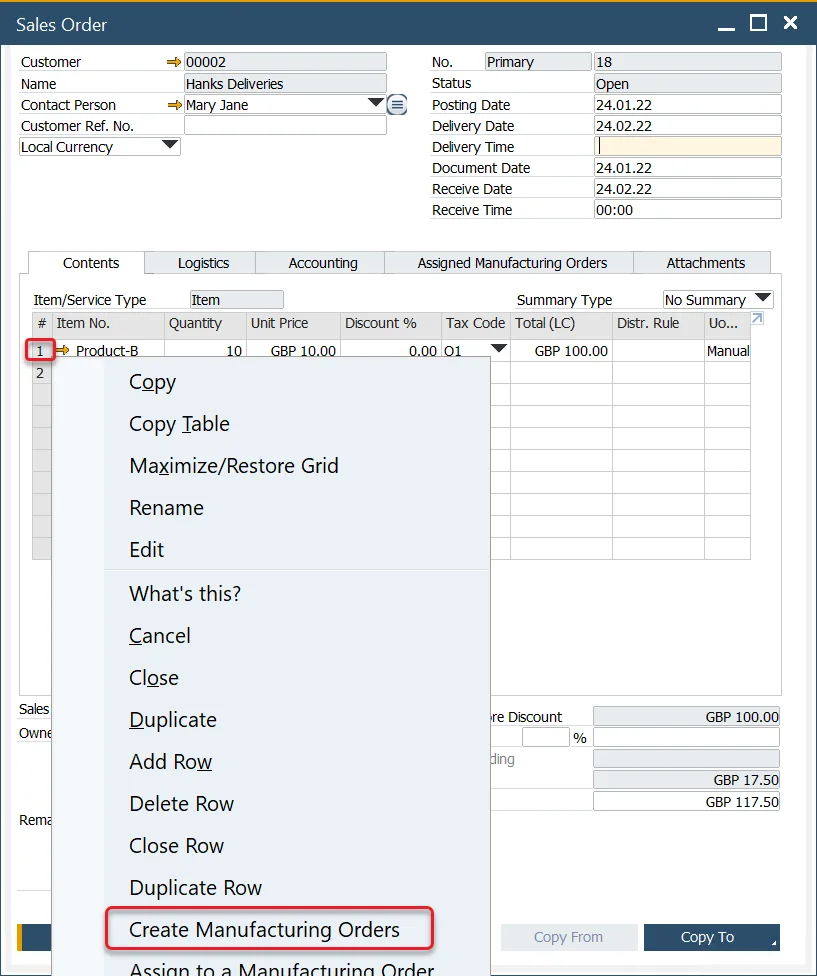

Semi-finished product Manufacturing Orders can be created from the Sales Order context menu. Simply choose the Create Manufacturing Orders option:

Two options are available in the context menu:

- Create Manufacturing Orders: opens the Scheduling Board

- Create Manufacturing Order: creates a single Manufacturing Order for the item in the Content tab. Clicking this option opens the context menu.

Manufacturing Order

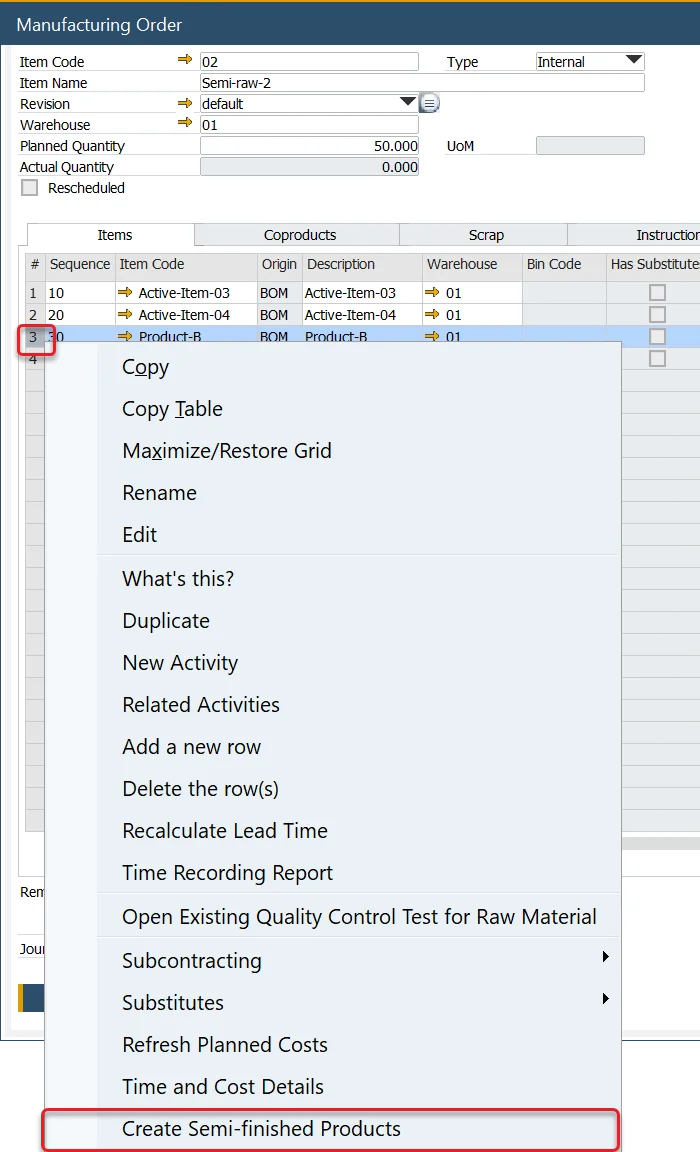

Semi-finished products can also be created via the context menu of a final goods Manufacturing Order:

- After creating semi-finished product Manufacturing Orders, an additional option becomes available in the context menu: Scheduling → Recalculate Semi-finished Products Lead Time.

- This opens the Semi-finished Product Scheduling Board, allowing you to adjust Manufacturing Order dates and recalculate Lead Time.

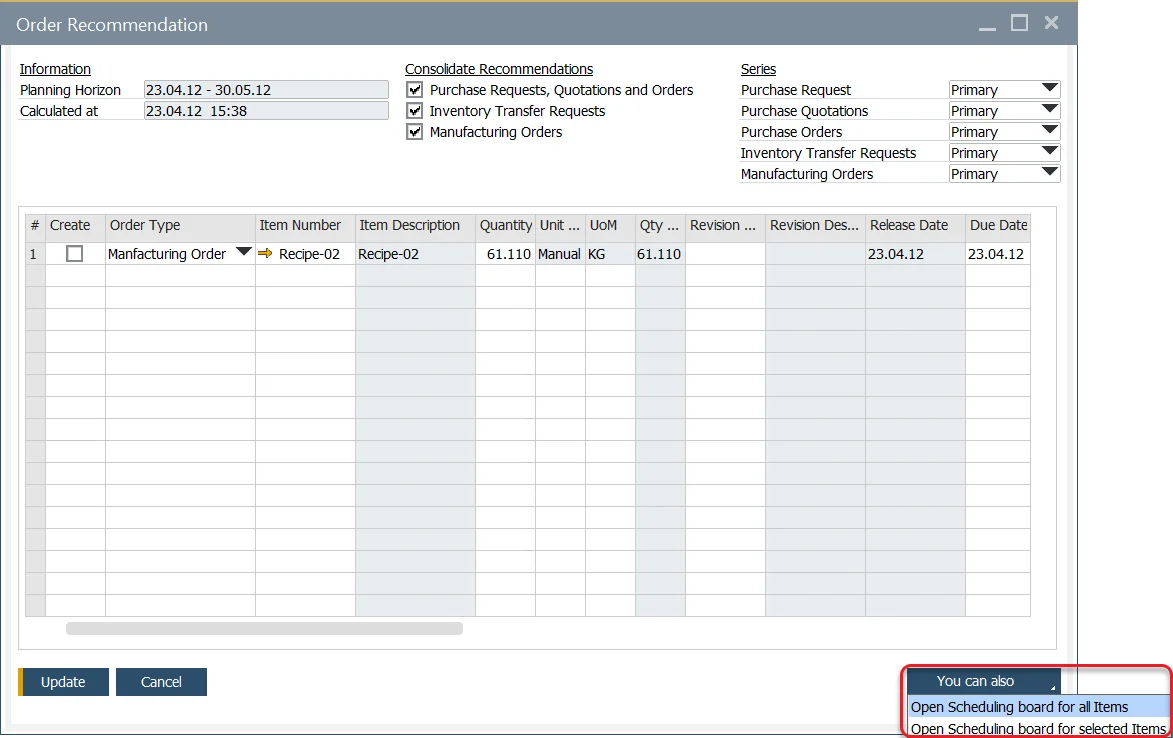

Order Recommendation

MRP → Order Recommendation

The Scheduling Board can also be accessed from the Order Recommendation form:

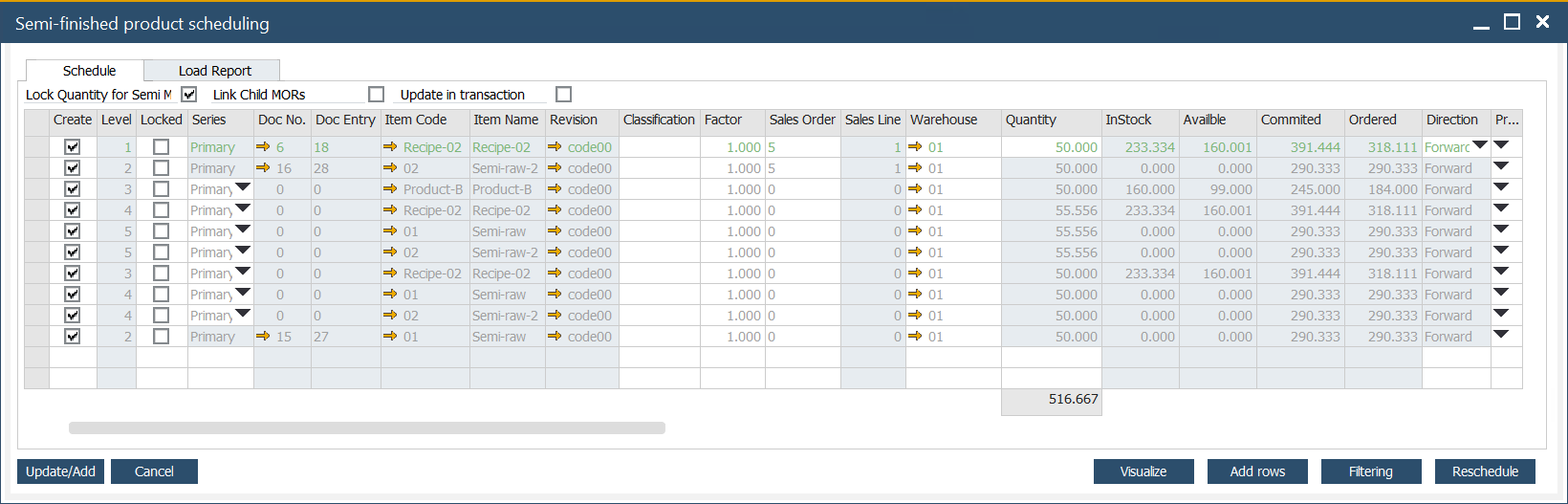

Scheduling Board / Semi-finished Product Scheduling

Semi-finished product scheduling is a tool for production planning, considering a product structure.

Schedule tab

Create

This checkbox determines whether a Manufacturing Order for the Item will be scheduled for creation.

The checkbox cannot be checked if a higher-level item is disabled.

Level

Indicates the item's position in the production structure. For items with semi-finished components, the hierarchy level is shown here. Learn more about multi-level BOMs and semi-finished items here.

Quantity

Displays the planned item quantity. You can modify quantities at level 1, and changes will automatically cascade to lower levels.

Lock Quantity for Semi MORs

If the checkbox is checked, there is a possibility to change the quantity for a particular item. In this case, changing one thing does not affect other items.

Update in Transaction

When you click Update/Add on the Scheduling Board, the listed Manufacturing Orders will be processed. However, some Manufacturing Orders may not be added due to issues like synchronization errors or incorrect data configurations. In such cases, an error message will be displayed.

- The checkbox is checked: none of them will be added if there is at least one Manufacturing Order with an error.

- The checkbox is not checked: if there are Manufacturing Orders with errors, the correct ones will be added anyway (and the ones with mistakes not).

Direction

Production can be planned in two ways:

- Forward: the system automatically plans forward the start and end of the day, absolute time, and required date.

- Backward: the system automatically plans backward start and end day, absolute time, and required date. Sometimes it is impossible to make items to the required delivery date. The text on the scheduling board is red.

Priority

Sets the priority level of the production order.

Schedule Date and Time

Specifies the planned schedule's start and end date/time.

Date and Time of end of the Order

Routing

Available routing can be chosen from the Scheduling Board.

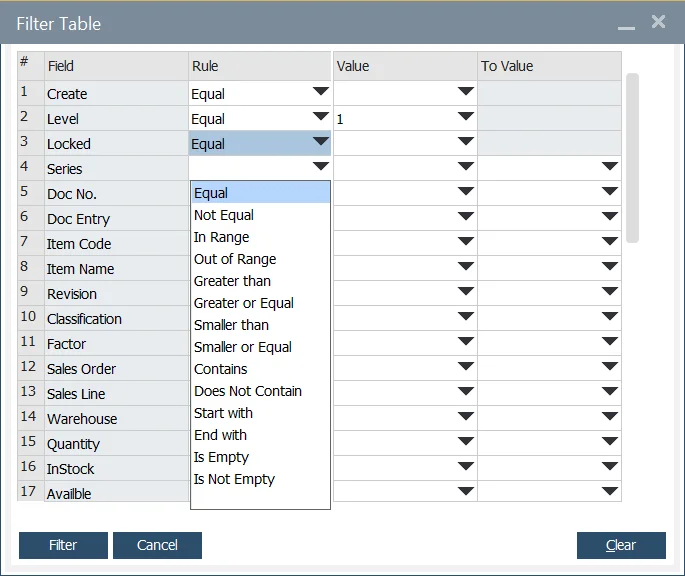

Filtering Option

The option allows filtering Manufacturing Orders based on the standard SAP Business One option.

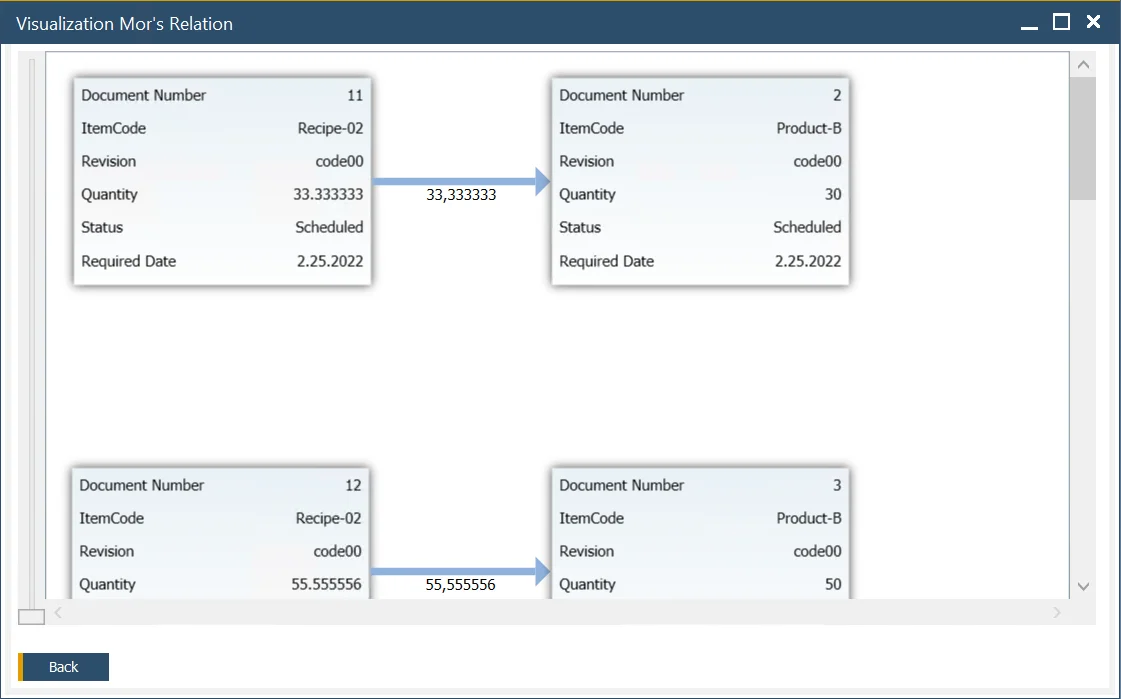

Visualize

Clicking this option opens a visual representation of relations between Manufacturing Orders:

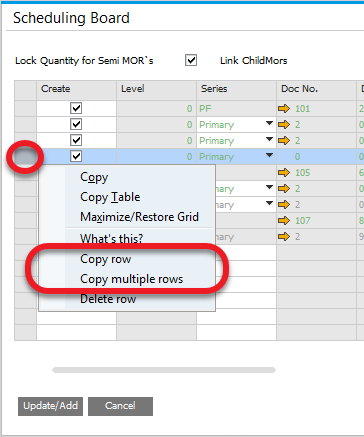

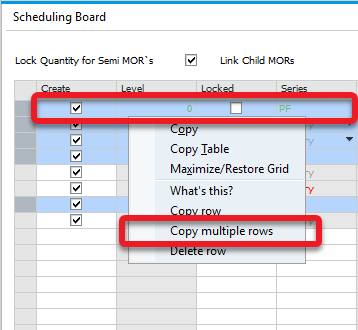

Copy row, Copy multiple rows

Options for copying one or multiple rows are available from the context menu in the first column.

To copy multiple rows, highlight them using Shift + Left Click or Ctrl + Left Click, then right-click on any column (except the first one) to access the option:

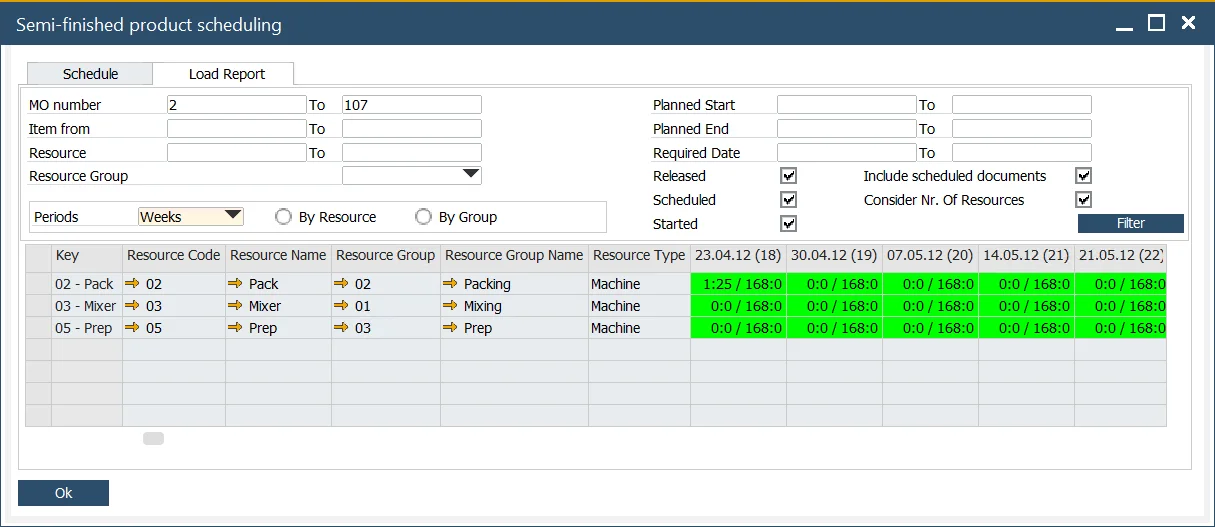

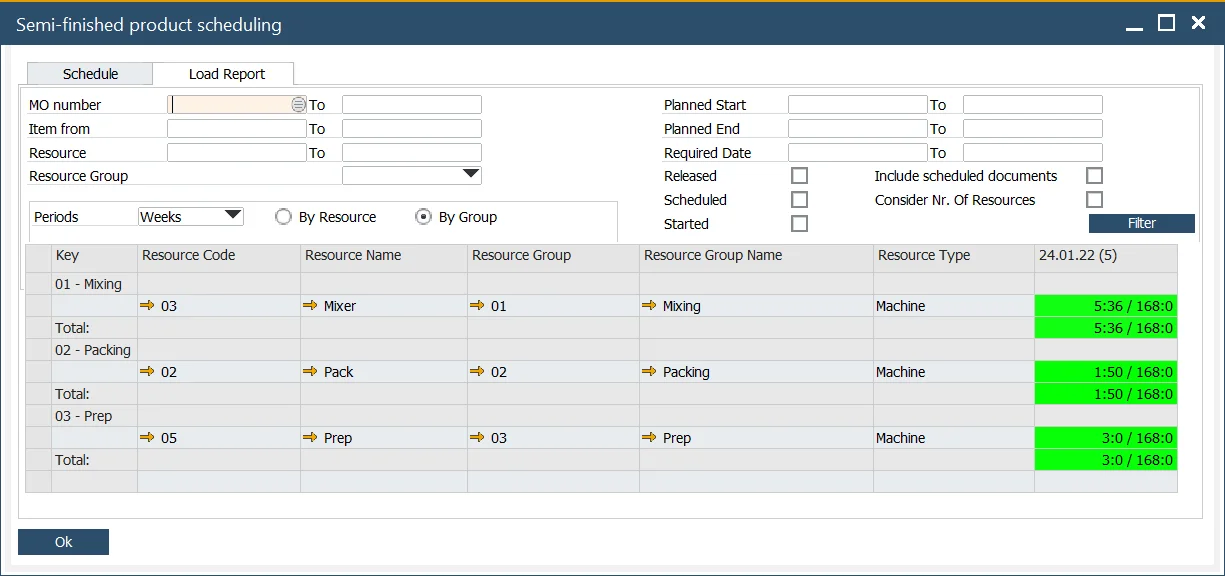

Load Report tab

The Load Report tab provides a summary of resource usage, including Set Up Time, Run Time Machine, and Labor Resources, for a specific time period.

This report takes into account all data calculated within the Schedule tab, even if the documents have not yet been saved or created.

In the time columns (adjacent to the Resource Type column), values such as 1:25 / 168:00 indicate the aggregated scheduled time and the total availability based on the corresponding Resource Calendar.

Filtering options:

-

MO number: filter by specific Manufacturing Orders.

-

Item: filter by Final Good Items.

-

Resource: filter by specific Resources used in the Manufacturing Orders.

-

Resource Group: filter Manufacturing Orders that involve at least one Resource from the selected group.

-

Planned Start, Planned End, Required Date: filter based on the Manufacturing Order dates.

-

Released, Scheduled, Started: filter by the status of Manufacturing Orders.

-

Periods: aggregate data into daily, weekly, or monthly intervals (columns right of the Resource Type column).

-

By Resource/ By Group: Display data either as a list of Resources or grouped by Resource Group, including a total for each group:

Example

To understand how the Scheduling Board operates, let’s walk through an example of creating a Sales Order and determining its Delivery Date.

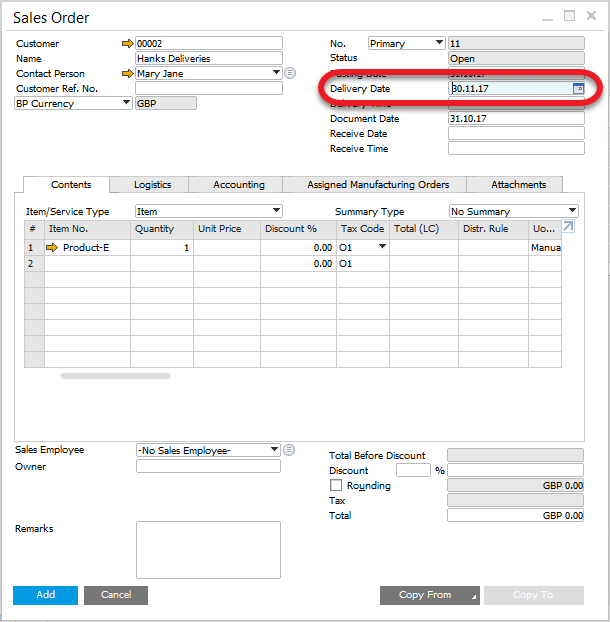

Step 1: Create a Sales Order

Set up a Sales Order and specify its Delivery Date in the order header.

Sales A/R > Sales Order

Step 2: Evaluate Manufacturing Possibilities

To assess whether the item can be produced in time, right-click on the item within the Sales Order and select Create Manufacturing Orders.

The system automatically considers the Delivery Date, the Internal Lead Time, and plans the Start Date backward. If the calculated Start Date falls earlier than today, the system switches to Forward scheduling and calculates the earliest possible End Date instead.

Let's consider two scenarios - Delivery date is possible to realize it and Delivery date is not possible to realize:

-

Delivery date is possible to realize it.

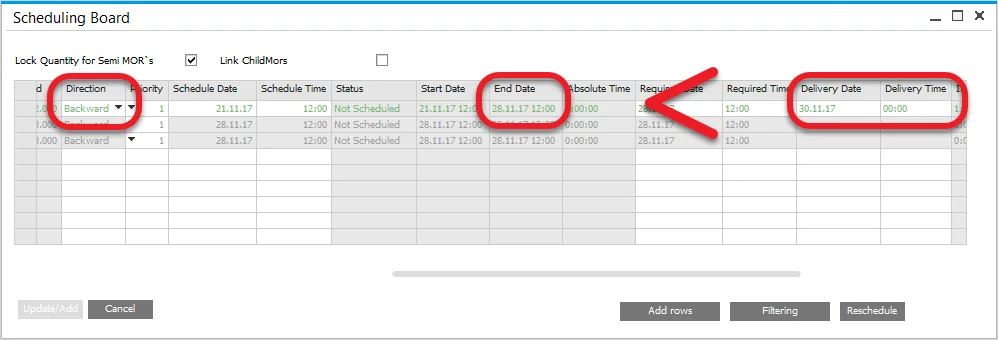

If the delivery date can be met, the Scheduling Board copies the delivery date and verifies if production can be completed on time.

In this example, the system determines that to meet the Delivery Date of 30.11.17, 0:00, production must finish by 28.11.17, 12:00. The green row on the Scheduling Board confirms that the Manufacturing Orders can be scheduled and delivered on time.

-

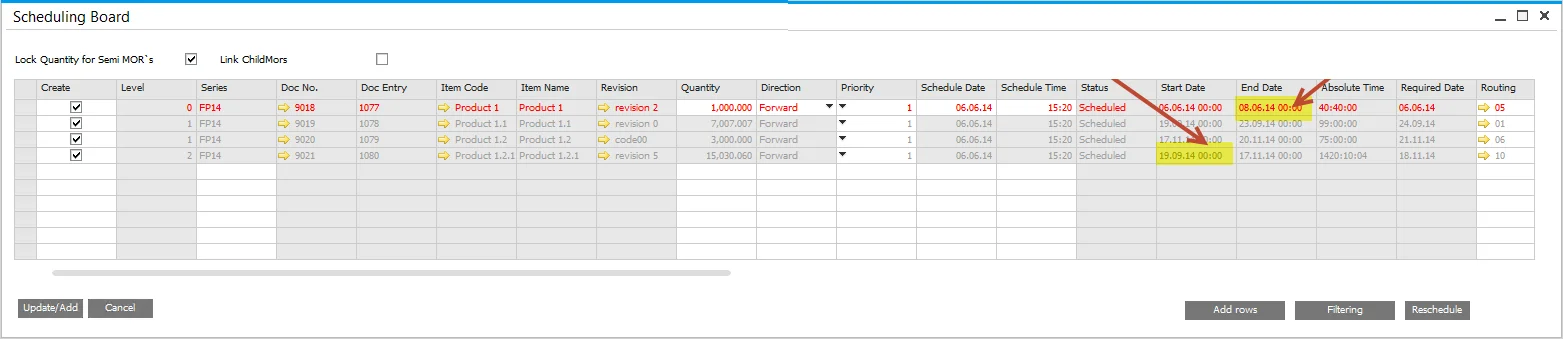

Delivery date is not possible to realize.

If meeting the Delivery Date is not feasible, the system automatically switches to Forward scheduling and calculates the earliest possible End Date.

As shown above, the system initially determines that production cannot be completed on time (indicated by the red row). It calculates the earliest possible End Date as 08.06, 00:00.

To reschedule, you can adjust the Delivery Date—for instance, changing it to 20.09 at 00:01—and switch the direction to Backward scheduling. After clicking Reschedule, the system recalculates the production timeline, and the row turns green, indicating that the Manufacturing Order can now be scheduled successfully.

Sales Order Minimum Order Quantity

This option allows considering Sales Order options (Minimum and Maximum Quantity, Order Multiple) when creating Semi Finished Manufacturing Orders suggestions on Scheduling Board. This gives the sales operator a tool to provide an accurate estimated arrival time.