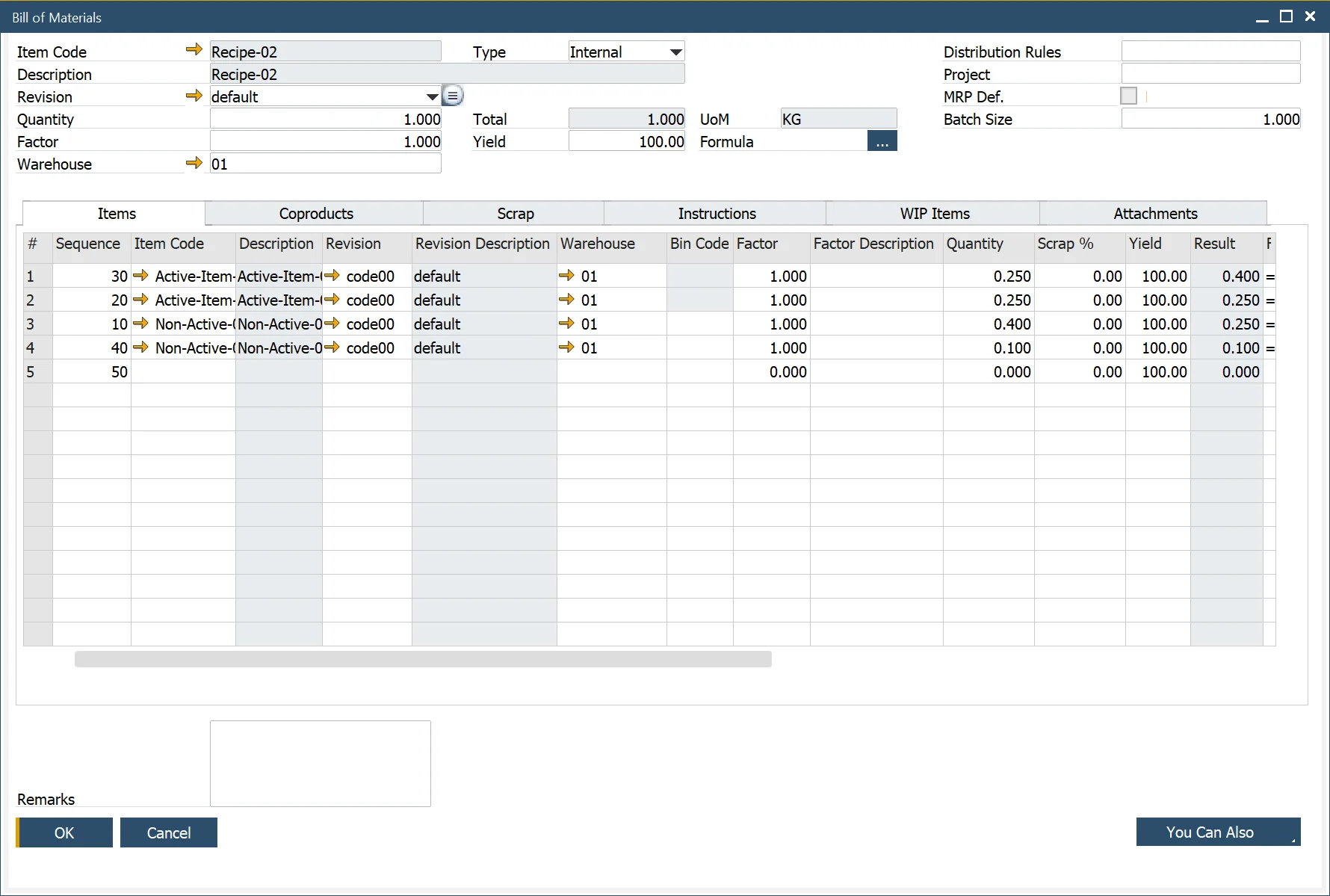

Bill of Materials form Header

The Bill of Materials (BOM) Header form enables users to define the structure of a Bill of Material for a final product or a component used in another Bill of Material. This feature ensures precise material management and production planning.

To access Bill of Materials form Header, navigate to:

Path

Production → Bill Of Materials → Bill of Materials → Header

Key Features

- Multiple BOM Versions: users can create multiple BOMs for a product based on the Revision Code, managed in Inventory → Item Details → Revision Tab. Learn more Click here to find out more.

- Quantity & UoM: specifies the required product quantity and unit of measure (UoM) for the parent item. The Quantity and UoM represent the product quantity of the parent item.

- Factor: defines variables affecting parent and component quantities, such as yield or scrap.

- Warehouse: identifies the production location.

- Type Field: indicates whether the product is Internal (produced in-house) or External (subcontracted).

- Distribution Rule & Project: optional fields for tracking financial and operational data.

- MRP Default: determines if this BOM is the default for Material Requirements Planning (MRP). If unchecked, the BOM does not sync with SAP Business One.

- Batch Size: defines production batch sizes to calculate costs, considering setup time, fixed runtime, stock, and queue time.