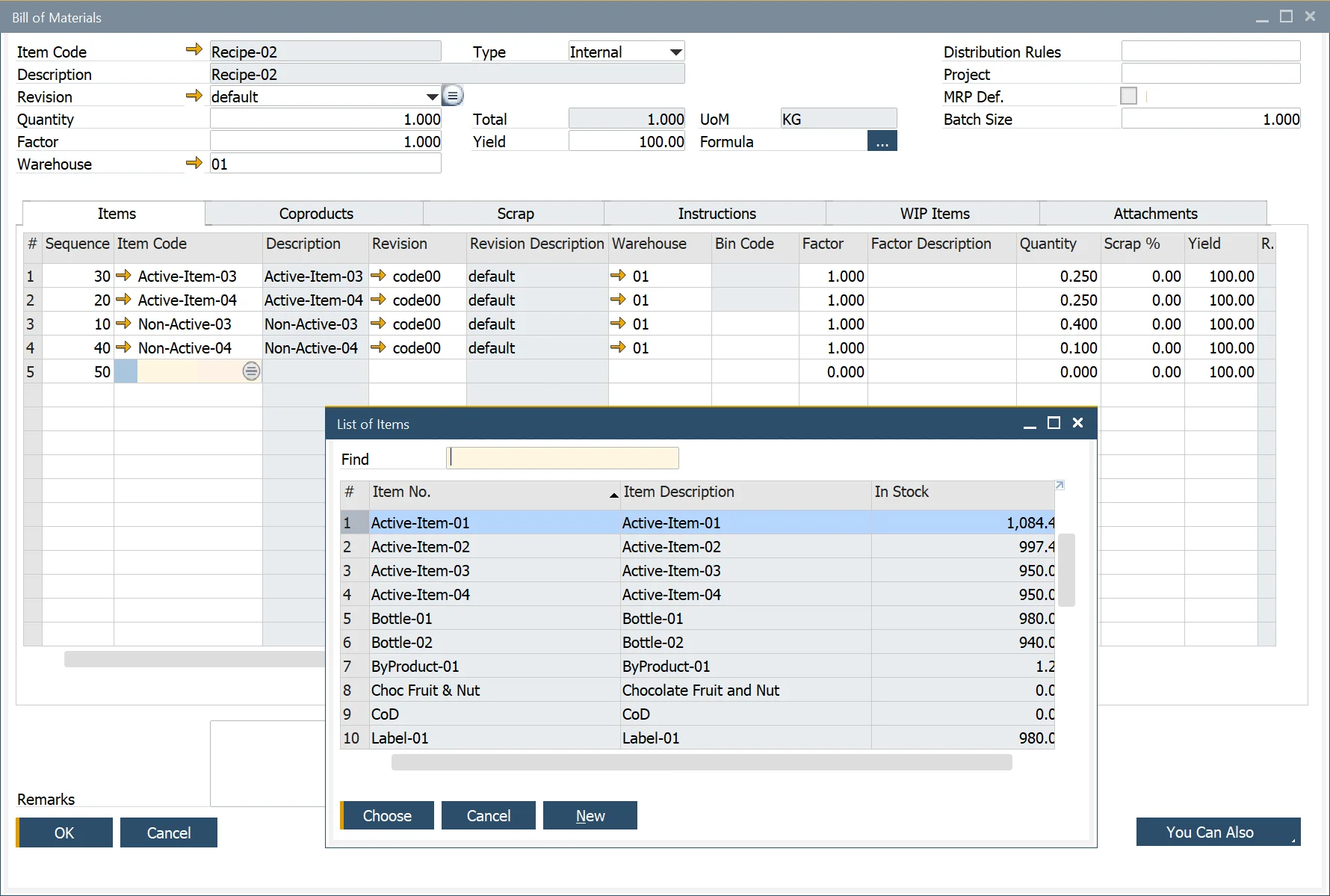

Items tab

In the Bill of Materials (BOM) module, the Items tab plays a crucial role in defining the components required to produce a parent product. This section allows users to manage and configure the materials, quantities, and related settings essential for the manufacturing process.

To access Items tab, navigate to:

Path

Production → Bill of Materials → Bill of Material → Items Tab

Key Functionalities

This form allows the user to perform the following:

- Component Entry: users can list all the components necessary for producing the parent product.

- Warehouse Assignment: specifies where the inventory is stored and, if backflushed, where deductions occur.

- Factor & Description: the Factor acts as a variable to adjust the quantity dynamically

- Quantity: users can set the number of items required per unit of the parent product.

- Scrap % Inclusion: accounts for expected material wastage, affecting the total item quantity.

- Result Calculation: automatically computes the relationship between item and parent product quantity using a predefined or customized Formula See Formula for additional information.

- Unit of Measure (UoM): defined in the Item Master Data/Inventory Tab, ensuring accurate unit tracking.

- Type (Make or Buy): display-only field that indicates whether the component is produced in-house or procured externally. This is determined in the Item Master Data/Planning Data Tab..

- Issue Type Selection: determines whether inventory issuance follows a Manual or Backflush method. The default setting is found in the Item Master Data/General Tab.

- Project Codes: allows users to assign project-specific codes to each line item for tracking purposes.