You are currently viewing documentation for CompuTec ProcessForce 3.0, which is a plugin installed and managed through CompuTec AppEngine 3.0, built on .NET 8.

If you are working with older environments, you may need the documentation for CompuTec ProcessForce 2.0, which is still supported: https://learn.computec.one/docs/processforce/2.0/.

Please note that CompuTec AppEngine 3.0 introduces a new architecture. All CompuTec components, including the CompuTec ProcessForce 3.0 plugin, must be updated together to ensure full compatibility.

Before starting your installation or upgrade process, we strongly recommend reviewing the CompuTec AppEngine 3.0 and CompuTec ProcessForce 3.0 documentation.

Basic Settings

MRP 2.5 in SAP Business One brings enhanced Material Requirements Planning (MRP) capabilities, enabling businesses to optimize procurement, production, and inventory management. This upgraded version introduces advanced forecasting, improved stock visibility, and flexible procurement settings tailored for efficient resource planning.

MRP 2.5 supports:

- Forecasting at the item and revision level

- Precise lead time and internal lead time configurations

- Inventory and order quantity controls

It integrates with CompuTec AppEngine, allowing seamless operation within SAP Business One.

How-To: Set Up and Configure MRP 2.5

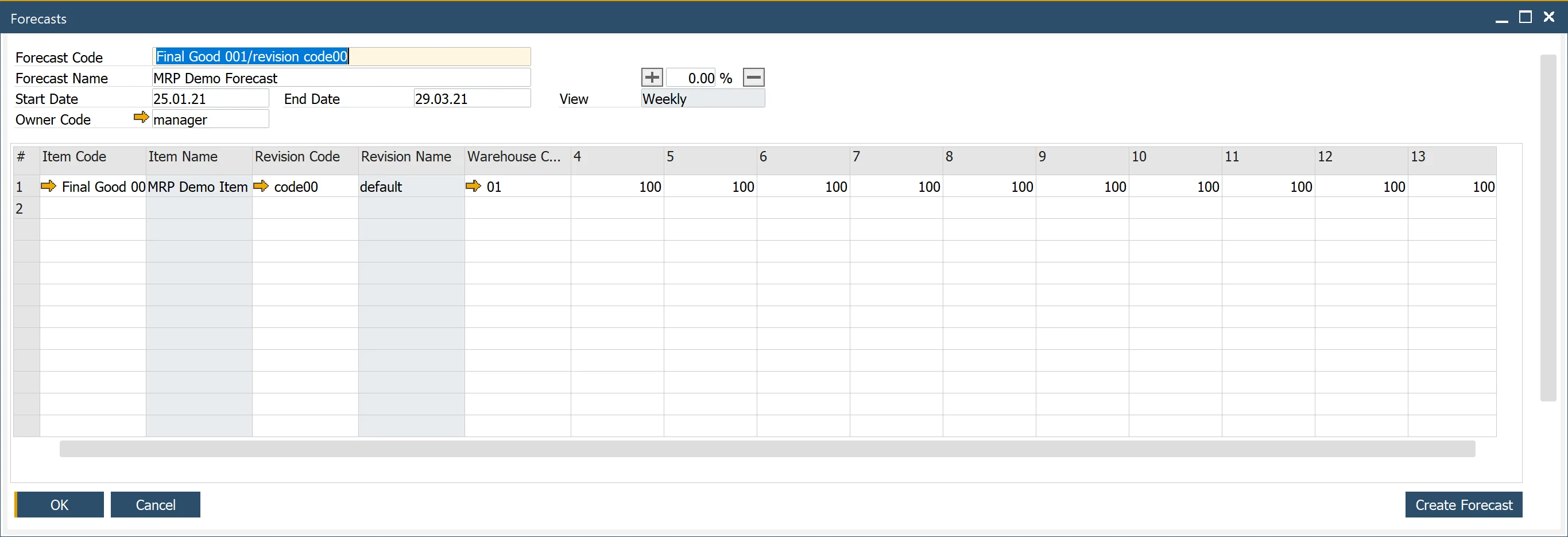

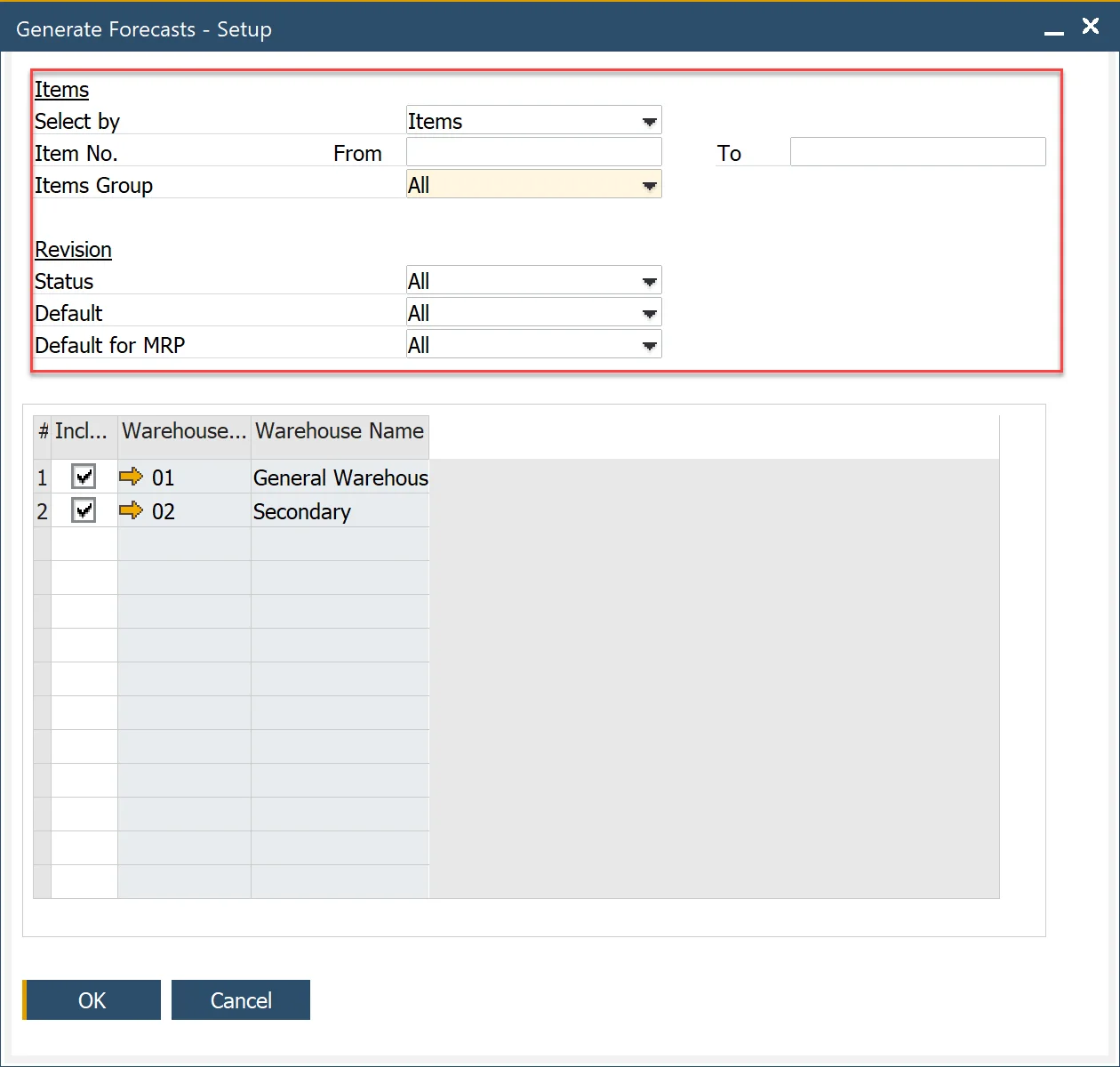

Step 1: Generate Forecasts Using Forecasts 2.5

To generate forecasts for MRP 2.5, use Forecasts 2.5, which allows forecast definition per Item/Revision.

Use the Create Forecast button to quickly add multiple forecast lines based on selection criteria.

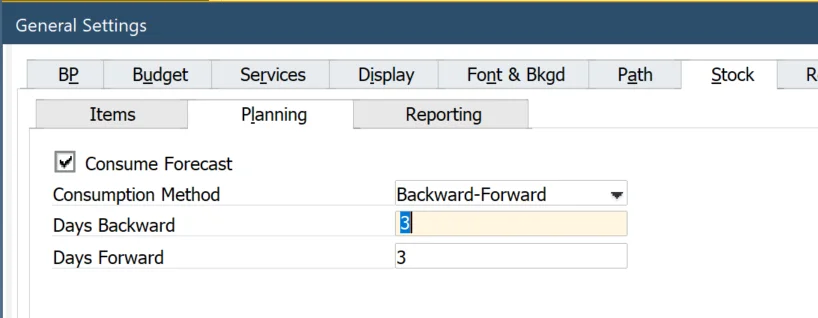

Step 2: Forecast Consumption in General Settings

Forecast consumption parameters are set in General Settings:

The General Settings define default parameters for MRP 2.5.

-

Consumption Method: Days Backward/Forward: Can be adjusted per scenario.

-

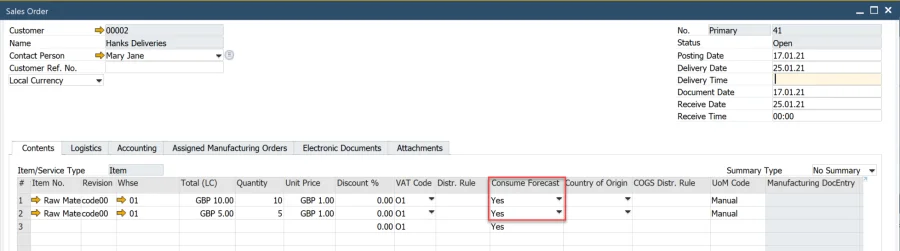

Consume Forecast: A global setting that determines forecast consumption in sales document lines under the Consume Forecast column.

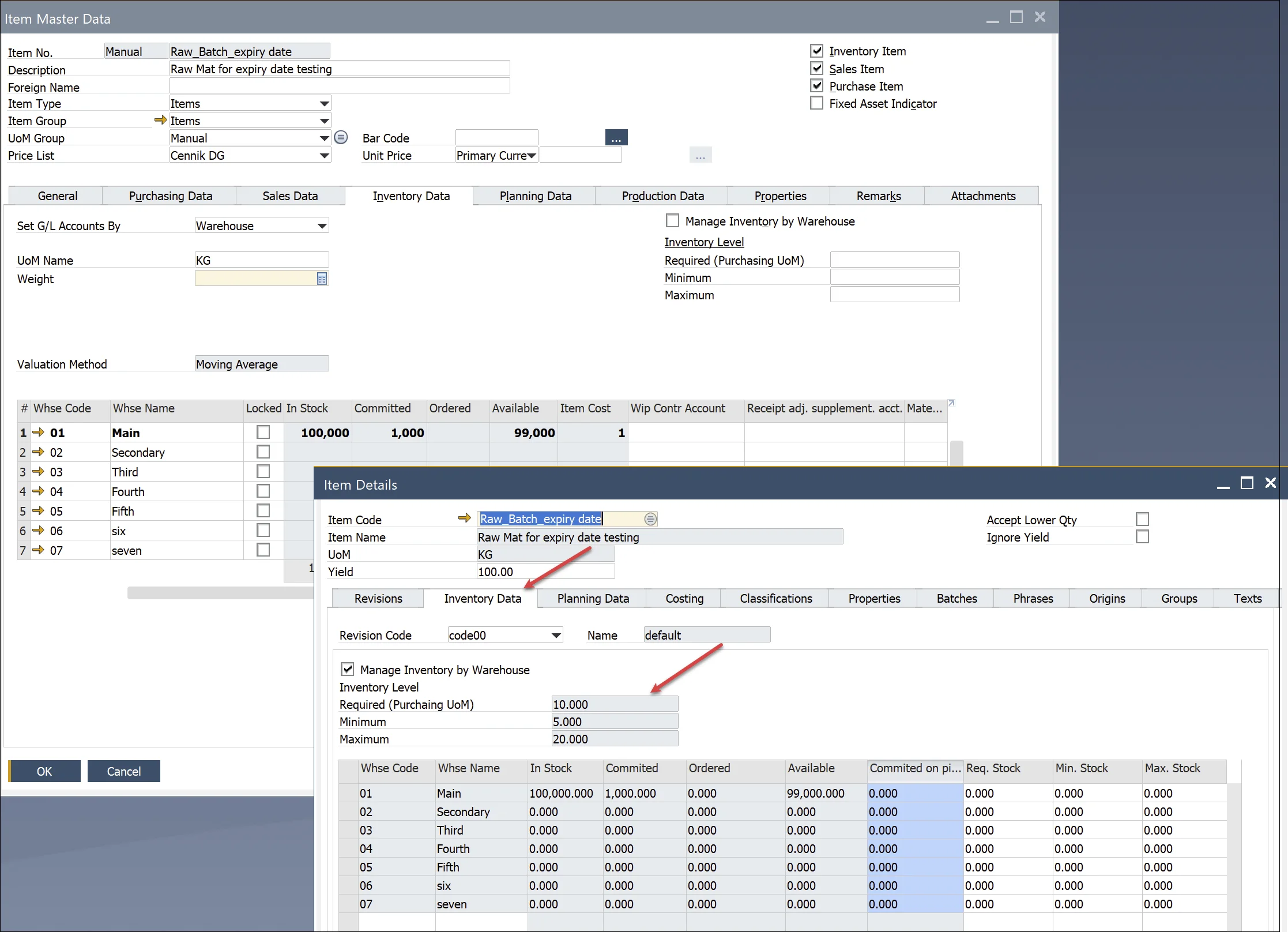

Step 3: Configure Item/Revision Planning Data

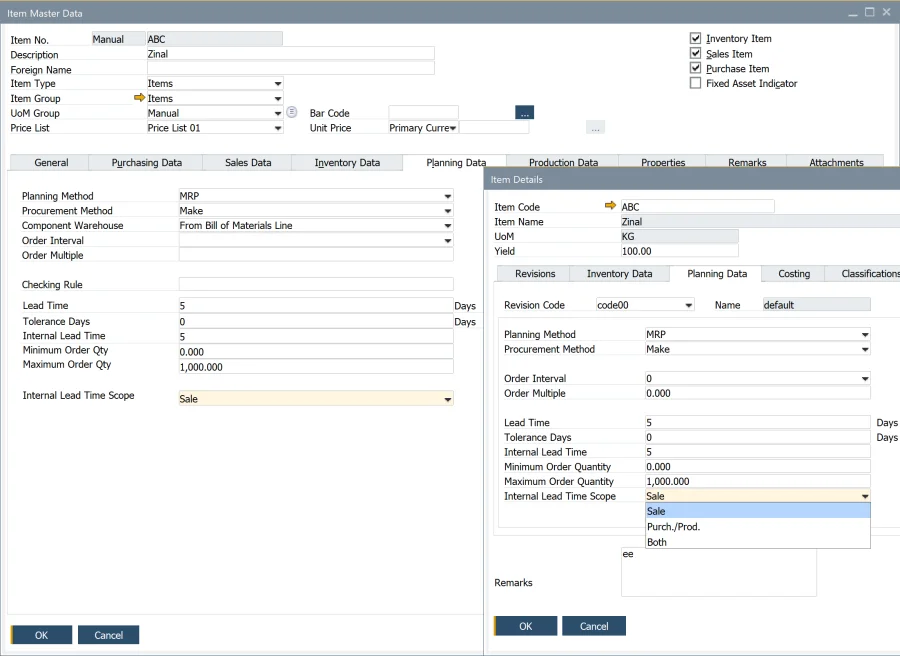

Planning data is defined in the Item Master Data and separately for each Item Revision under Item Details.

- Planning Method: Functions similarly to standard SAP Business One MRP.

- Procurement Method: Supports both Make and Buy, working as in standard SAP Business One.

- Component Warehouse: Can be determined from the Bill of Materials (BOM) Line or Parent Item Document Line, similar to the standard version.

- Order Interval: Choose from predefined intervals or create a custom interval using the Order Interval - Setup window. The system groups recommended orders into defined periods, scheduling them on the first working day within that period.

- Checking Rule: Not ready for tests.

- Tolerance Days: Not ready for tests

- Lead Time (LT): Enter the number of days from when the item is ordered to when the item is received or produced.

Example

If the lead time is for three days, the MRP will issue the purchase or production order for the child items with a due date three days before the parent item's due date. In other words, we need three days to produce (Procurement Method = Make) or send the item by the supplier (Procurement Method = Buy).

Example: Holidays, Lead Time, and Order Interval in MRP Calculations

Step 4: Configure Internal Lead Time (ILT)

Internal Lead Time (ILT) – additional time calculated for documents/recommendations. The calculation depends on the Procurement Method and ILT Scope. For example, internal testing time.

Internal Lead Time Scope – determine how ILT is added to documents/recommendations.

| Procurement Method | ILT Scope | Outcome | |

|---|---|---|---|

| 1a | Make | Sale | ILT added to Sales document |

| 1b | Make | Purch. / Prod. | ILT added to MOR document/recommendation (Supply) |

| 1c | Make | Both | ILT added to Sales document and MOR document/recommendation (Secondary Demand) |

| 2a | Buy | Sale | ILT added to Sales document |

| 2b | Buy | Purch. / Prod. | ILT added to Purchase document/recommendation |

| 2c | Buy | Both | ILT added to Sales document and Purchase document/recommendation |

Example

- Item with Procurement Method = Make, Lead Time = 3, Internal Lead Time = 1,

- ILT Scope = Sale If it is an Item ordered by the customer, ILT will be added to the Sales Order. After three days of MOR’s Release Date, the Item will be available in stock (Lead Time=3), and one day of Internal Lead Time will be added before the Item will be ready to send to the Customer (for example, packing time, quality control before packing, etc.). ILT will not be added to the finished MOR.

- ILT Scope = Purch. / Prod. ILT will be added only to the finished MOR. After three days of MOR’s Release Date, the Item will be available in stock (Lead Time=3), and one day of Internal Lead Time will be added after finishing MOR (for example, quality control activities). ILT will not be added to the Sales Order if it is an Item ordered by a customer.

- ILT Scope = Both

After three days of MOR’s Release Date, the Item will be available in stock (Lead Time=3), and one day of Internal Lead Time will be added:

- to Sales Order if it is an Item ordered by the customer, like in 1.1. In such a case, ILT will not be added to MOR.

- to MOR if it is not an Item ordered by the Customer. For example, it is planned based on demand from the higher BOM level (secondary demand), Like in 1.2.

- Item with Procurement Method = Buy, Lead Time = 10, Internal Lead Time = 1

- ILT Scope = Sale If it is an Item ordered by the customer, ILT will be added to the Sales Order. After ten days of the Purchase Order Release Date, the Item will be available in stock (Lead Time=10), and one day of Internal Lead Time will be added before the Item will be ready to send to the Customer (for example, packing time, final quality control, etc.). ILT will not be added to the PO.

- ILT Scope = Purch. / Prod. ILT will be added to the Purchase Order. After ten days from the Purchase Order’s Release Date, the item will be available in stock (Lead Time=10). One day of Internal Lead Time will be added before the item is available for production or sale (for example, quality control activities for the purchased item). ILT will not be added to the Sales Order if it is an Item ordered by a customer.

- ILT Scope = Both.

After ten days of the Purchase Order’s Release Date, the Item will be available in stock (Lead Time=10), and one day of Internal Lead Time will be added:

- only to Purchase Order If it is an Item not ordered by a customer.

- Purchase Order and Sales Order If it is an Item ordered by a customer. Thus, Internal Lead Time will be doubled.

Note: The sum of Lead Time and Internal Lead Time determines item availability for subsequent activities like production or sale.

Step 5: Define Order Quantity Rules

- Order Multiple: Order recommendations are rounded up to the nearest multiple of the defined value.

- Minimum Order Qty: If the recommended quantity is below this threshold, it is adjusted accordingly.

- Maximum Order Qty: When demand exceeds the defined maximum, the system creates multiple recommendations equal to the Maximum Order Quantity. The remainder is adjusted using the Minimum Order Quantity.

Note: Maximum Order Should be used with Minimum Order Quantity.

Examples of order Qty calculations:

Example 1

Parameters:

- Order Quantity = 103

- Order Multiple = 3

- Minimum Order Qty = 5

- Maximum Order Qty = 10

Outcome:

- 10 recommendations with a quantity of 10 each.

- Rest of division = 3 (Order Quantity/Maximum Order Qty)

Last (11) recommendation with quantity 5 (effect of Minimum Oder Quantity, Rest of division < Minimum Order Qty)

Example 2

Parameters:

- Minimum Order Qty = 2 (other parameters unchanged)

Outcome:

- The first ten recommendations with quantity 10

- Rest of division = 3 (Order Quantity/Maximum Order Qty)

Last (11) recommendation with quantity 6 (effect of Order Multiply, Rest of division < Minimum Order Qty)

Step 6: Configure Item/Revision Stock Data

For batch-managed and serial-numbered items, MRP 2.5 provides enhanced visibility into stock levels. Inventory level parameters can be managed per revision and per item, allowing businesses to maintain precise inventory control.