You are currently viewing documentation for CompuTec ProcessForce 3.0, which is a plugin installed and managed through CompuTec AppEngine 3.0, built on .NET 8.

If you are working with older environments, you may need the documentation for CompuTec ProcessForce 2.0, which is still supported: https://learn.computec.one/docs/processforce/2.0/.

Please note that CompuTec AppEngine 3.0 introduces a new architecture. All CompuTec components, including the CompuTec ProcessForce 3.0 plugin, must be updated together to ensure full compatibility.

Before starting your installation or upgrade process, we strongly recommend reviewing the CompuTec AppEngine 3.0 and CompuTec ProcessForce 3.0 documentation.

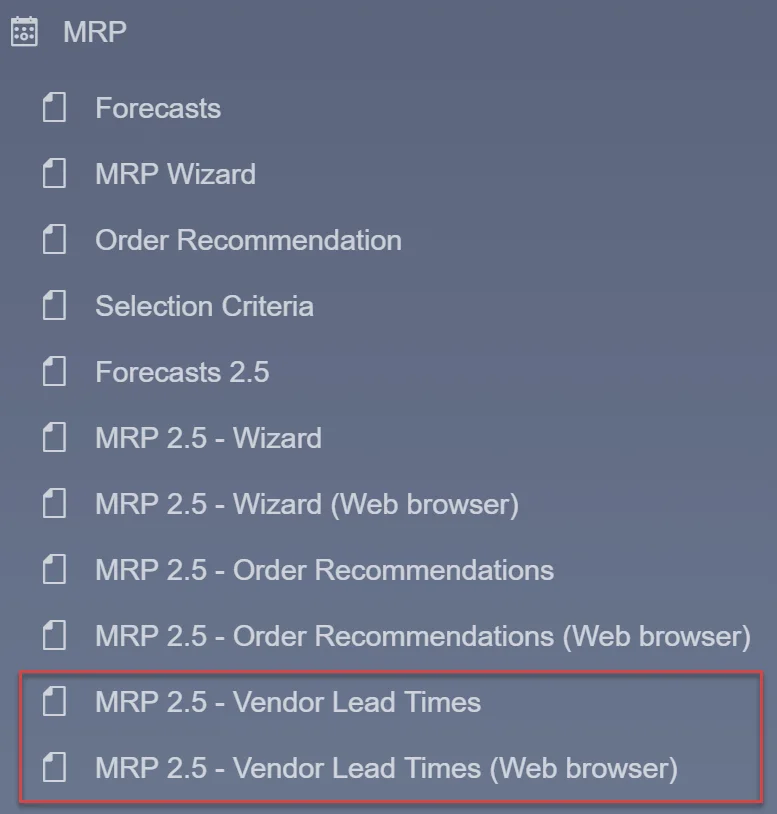

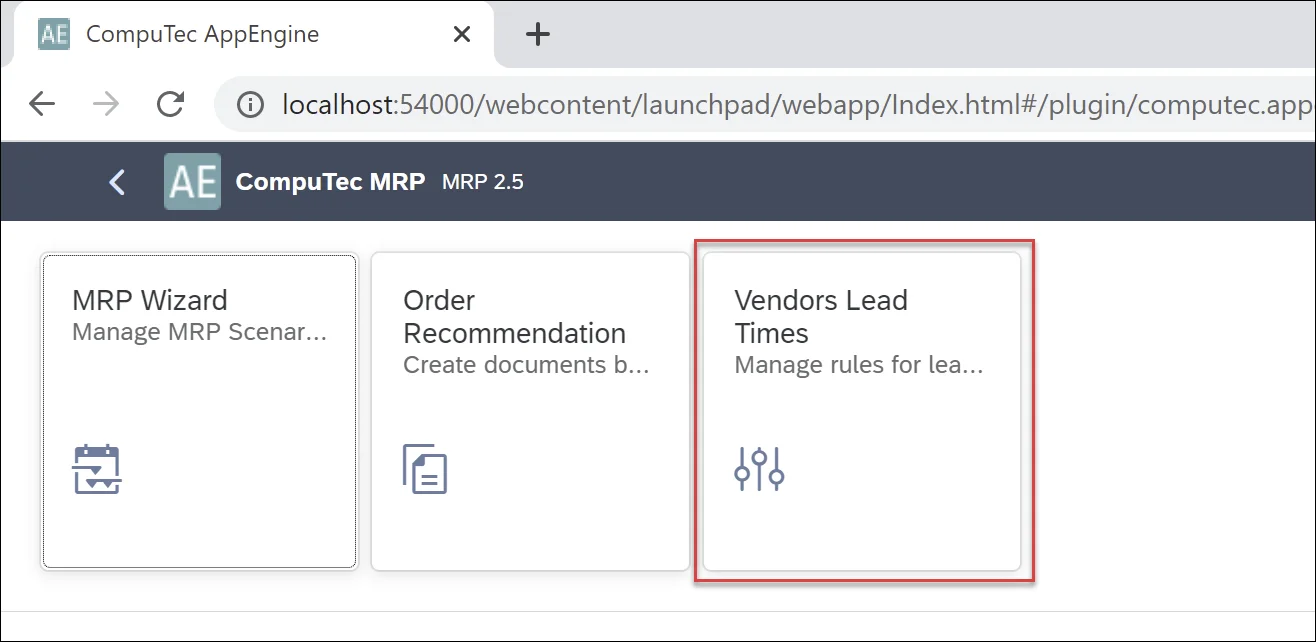

Vendors Lead Times

Effective management of vendor lead times is crucial for optimizing procurement and ensuring smooth production planning. In MRP 2.5, vendor lead times can be defined with varying levels of accuracy, considering vendor defaults, shipping types, and shipping addresses. This article outlines how vendor lead times are determined, the hierarchy of rules applied, and the role of internal vendor lead times in material planning.

Overview of Lead Time Precision Levels

MRP 2.5 allows vendor lead times to be defined at multiple levels, which are applied in a prioritized order:

- Vendor(default) & Shipping Type(default) & Shipping Address(default).

- Vendor(default) & Shipping Type(default).

- Vendor(default).

This hierarchy ensures that MRP recommendations are based on the most granular available data, improving the accuracy of delivery estimates.

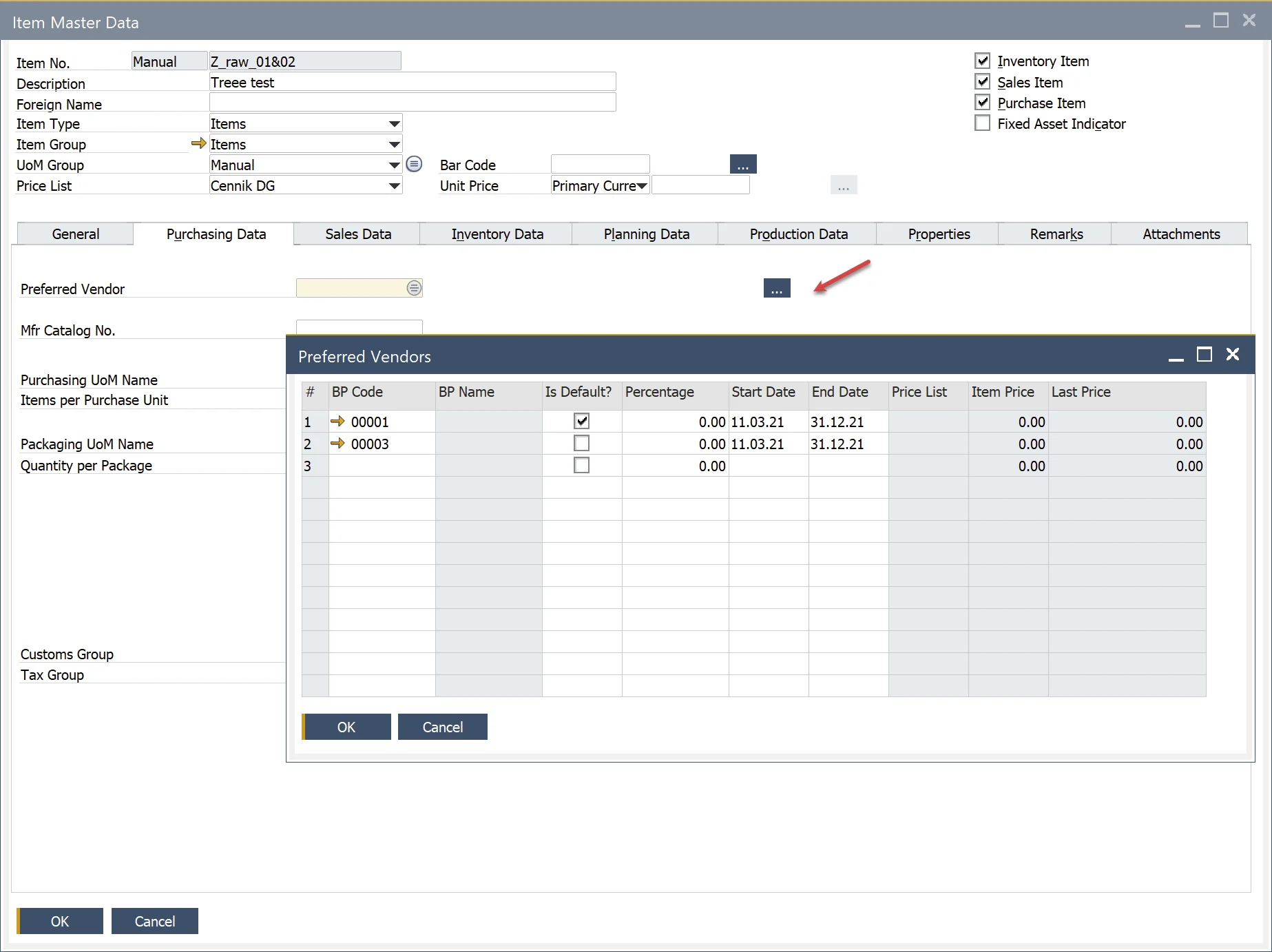

Default Vendor

A default vendor must be selected in the Item Master Data under the Purchasing tab to apply vendor-specific lead times.

Note: Only one vendor from the preferred vendor list can be assigned as the default.

Key Considerations

If the default Vendor is not defined in Item Master Data, then:

-

MRP will use the first vendor in the database for recommendations.

-

Lead time will be taken from Item Master Data (under Item Details for revisions), and vendor-specific lead time rules will not be considered. The rules for Vendor Lead Time are not considered in calculations.

-

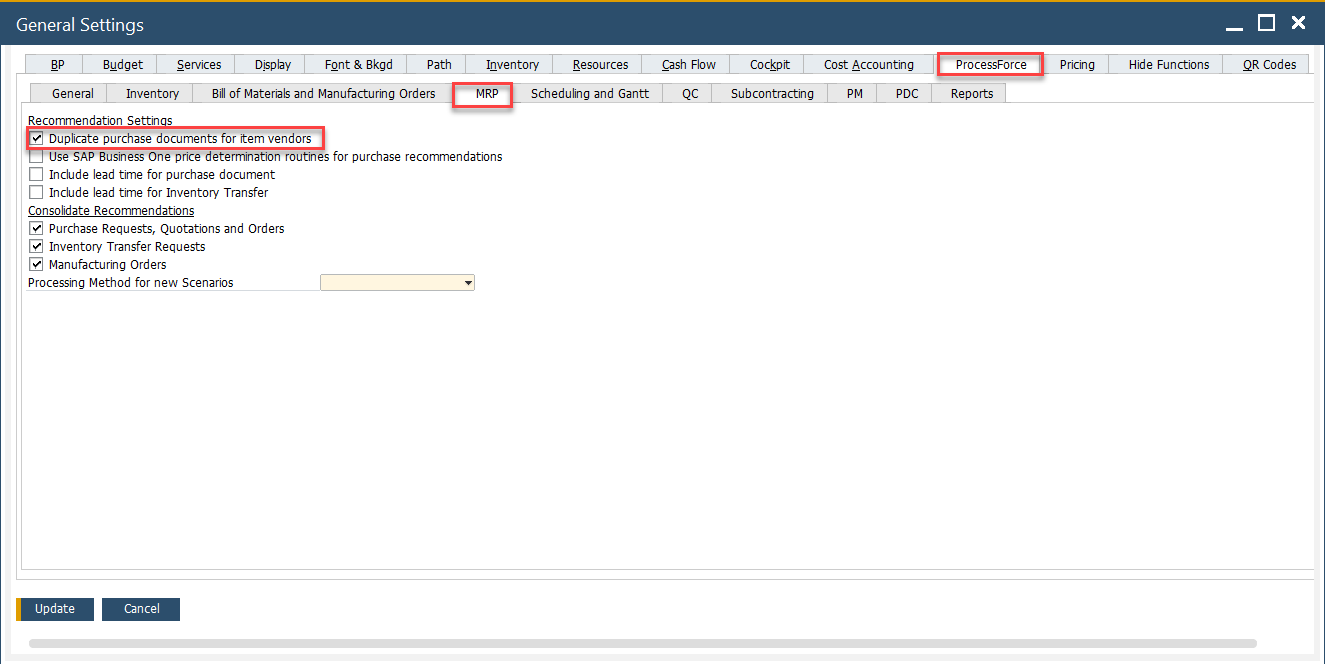

To define a default vendor, enable the "Duplicate purchase documents for item vendors" option in:

PathAdministration → System Initialization → General Settings → ProcessForce tab → MRP

Defining Shipping Types and Addresses

Each vendor can have several shipping types and addresses, but only one of each can be marked as default:

-

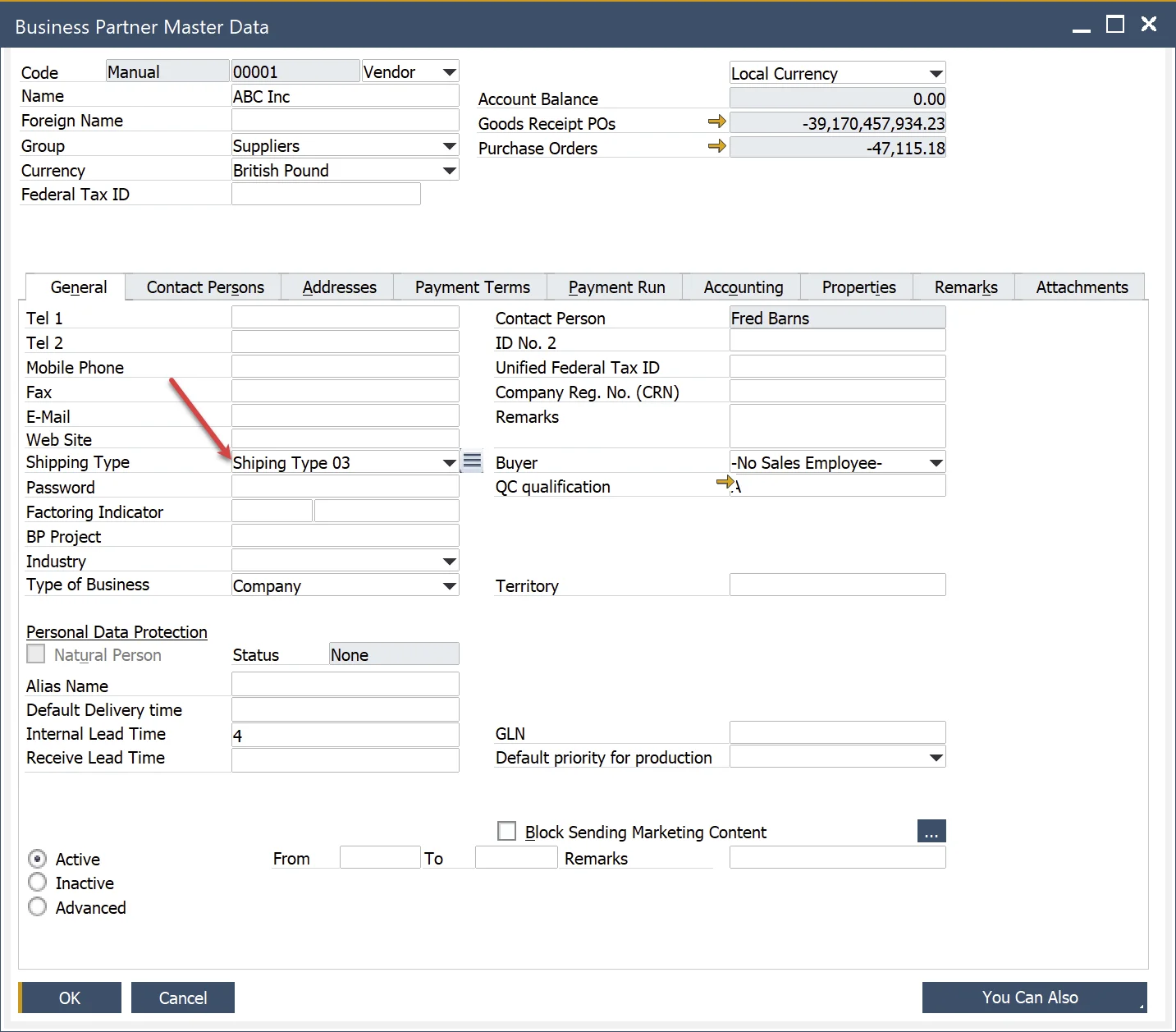

Shipping Type: Defined in Business Partner Master Data.

-

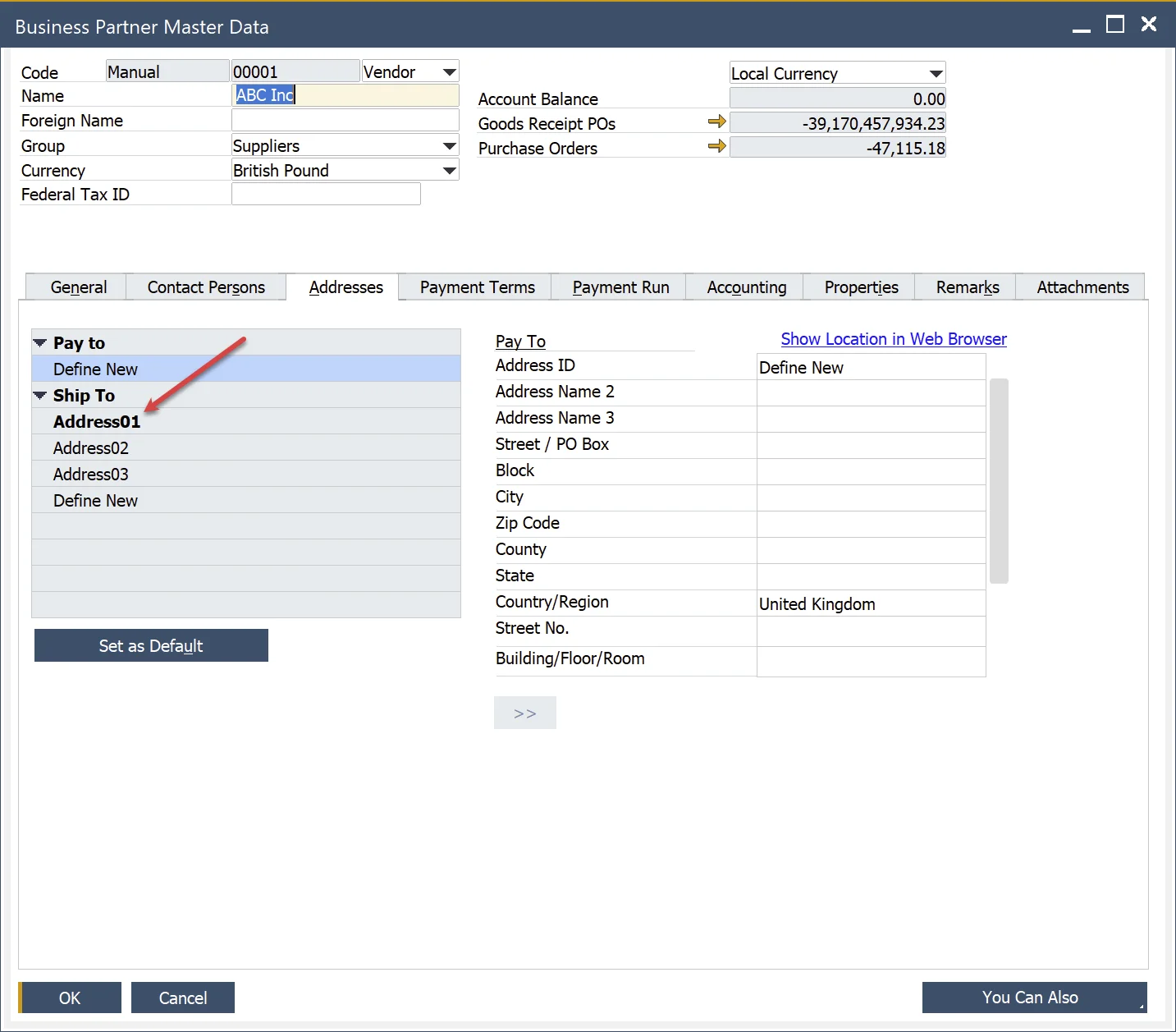

Shipping Address (Ship To): Also set in Business Partner Master Data.

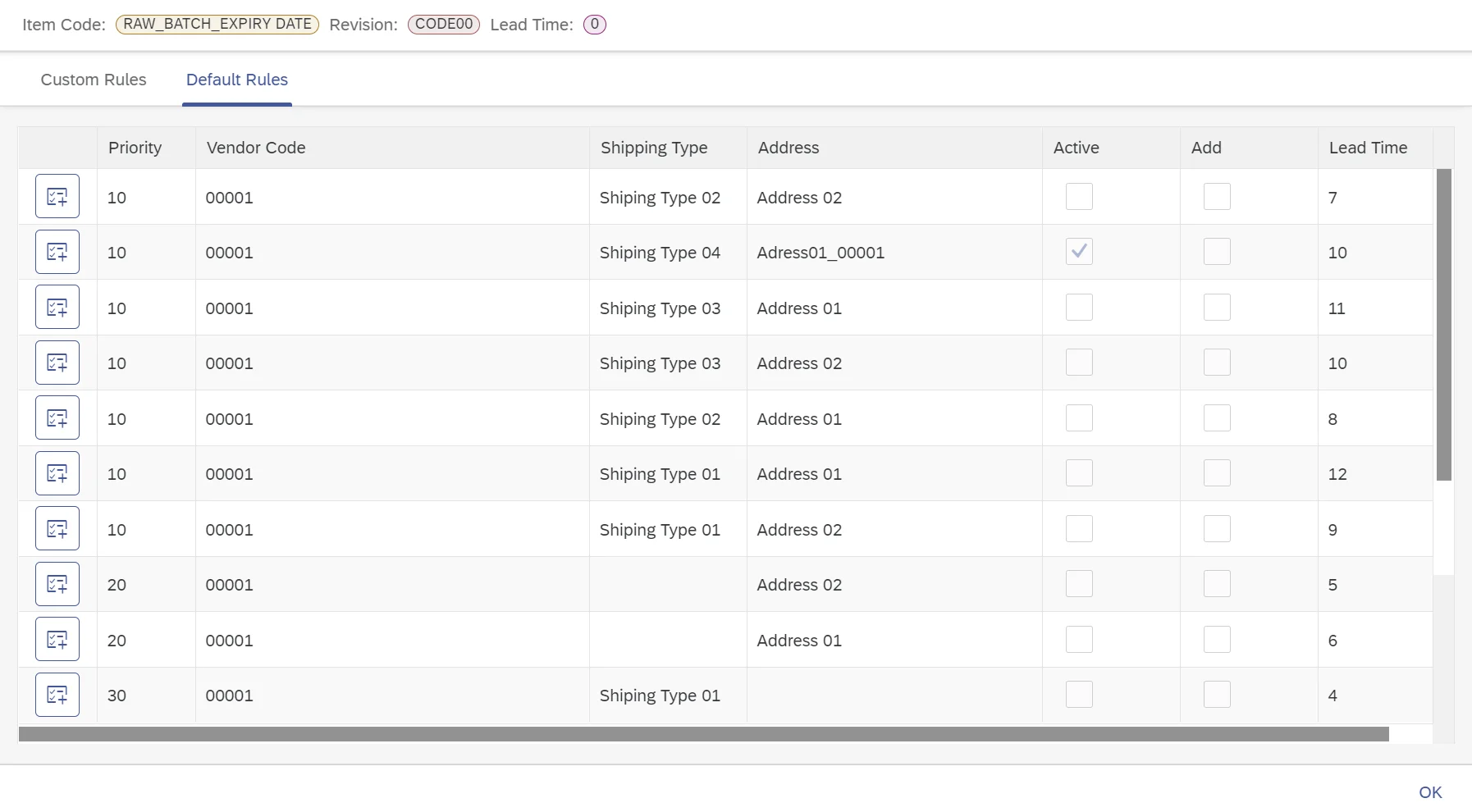

Vendor Lead Time Rule Hierarchy

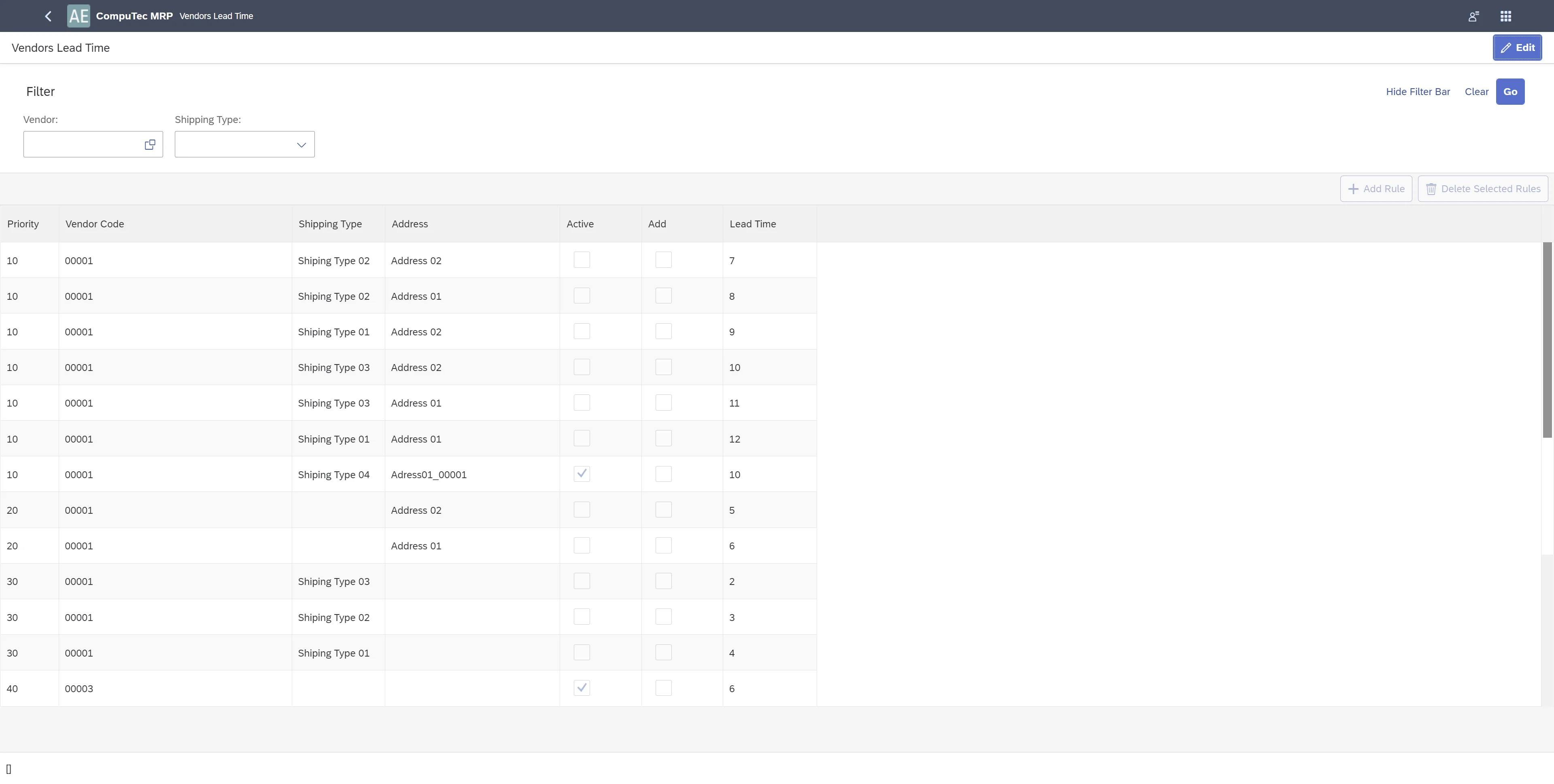

When generating MRP recommendations, the system applies lead time rules in the following order:

- At first, MRP 2.5 will try to find a rule with a match of all three components of the rule to these defined as default: Vendor(default) & Shipping Type(default) & Shipping Address(default).

- If MRP 2.5 does not find the above combination of Vendor(default) & Shipping Type(default) & Shipping Address(default), then it will try to find a match to Vendor(default) & Shipping Type(default).

- If MRP 2.5 does not find the above two combinations (pt. 1 & pt.2), then it will try to find a match to Vendor(default).

- If MRP 2.5 does not find any of the above, then it will use the Lead Time from Item Master Data (Item Details for revision).

You can deactivate any rule by unchecking the Active box or choose to add vendor lead time to item lead time using the Add option.

In MRP scenarios, these rules can be modified on a per-item basis.

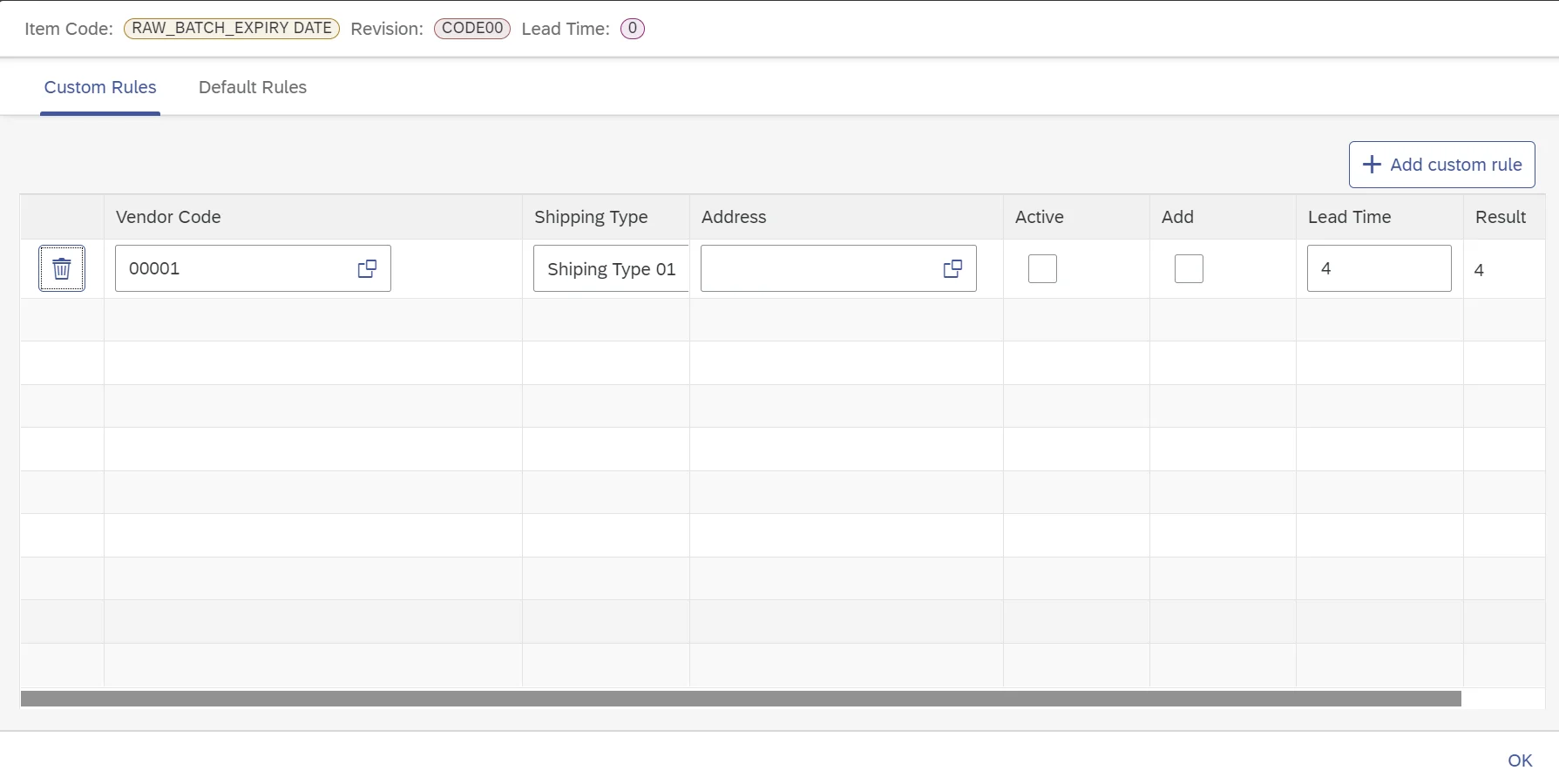

It is possible to add Custom Rules. You can do this by adding a new one or by copying from Default Rules. The rule can be edited there.

Custom Rules are overwritten Default Rules for the current scenario if they are identical. Edited rules/values are obligatory for the present scenario.

Important Notes

- Without a default vendor in the item master:

- The first Vendor in the database is proposed for recommendation.

- Lead Time is taken from Item Master Data (Item Details for revisions). The rules for Vendor Lead Time are not considered in calculations.

- Hierarchy of applying rules:

- Custom Rules

- Default Rules

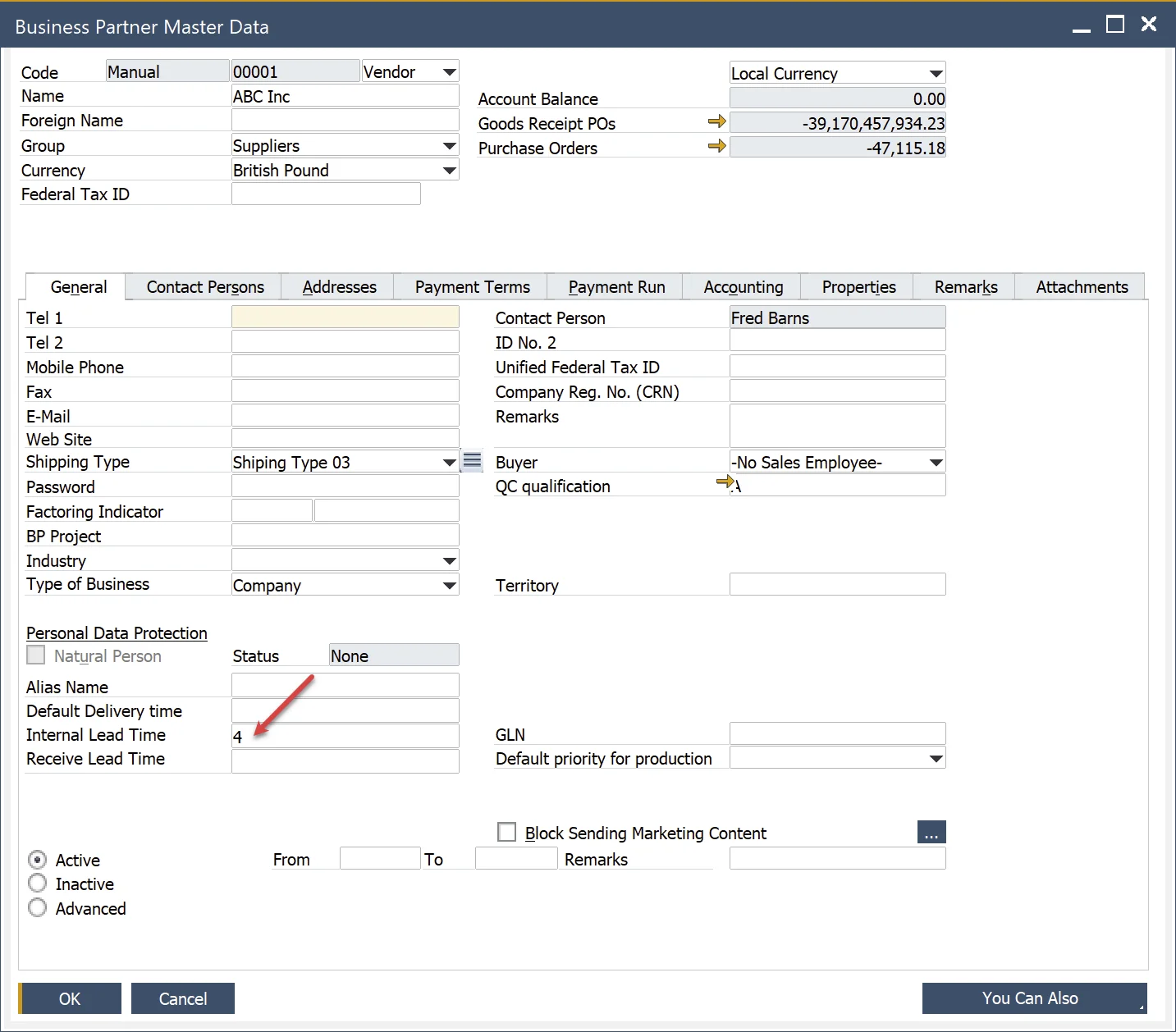

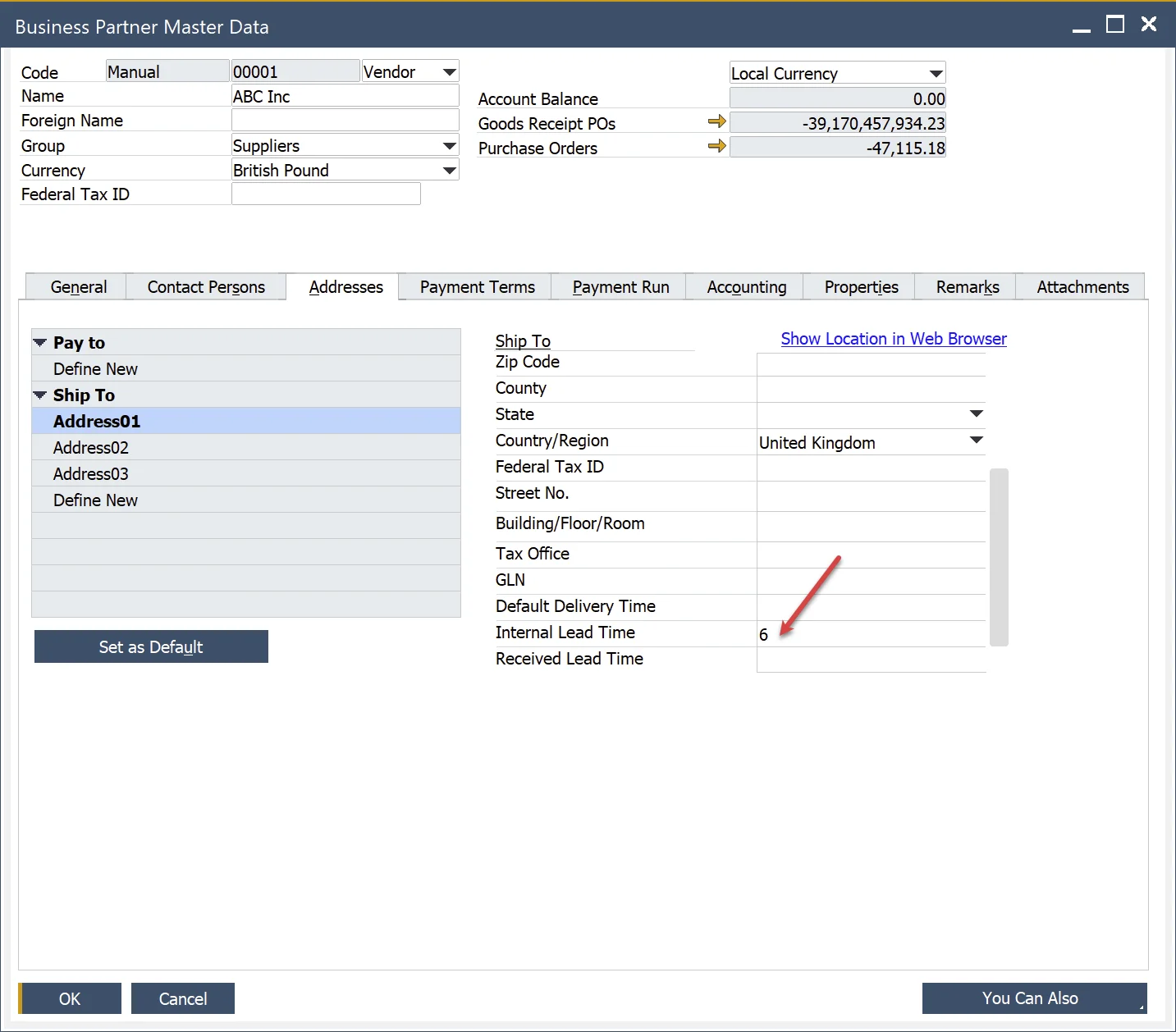

Internal Vendor Lead Time

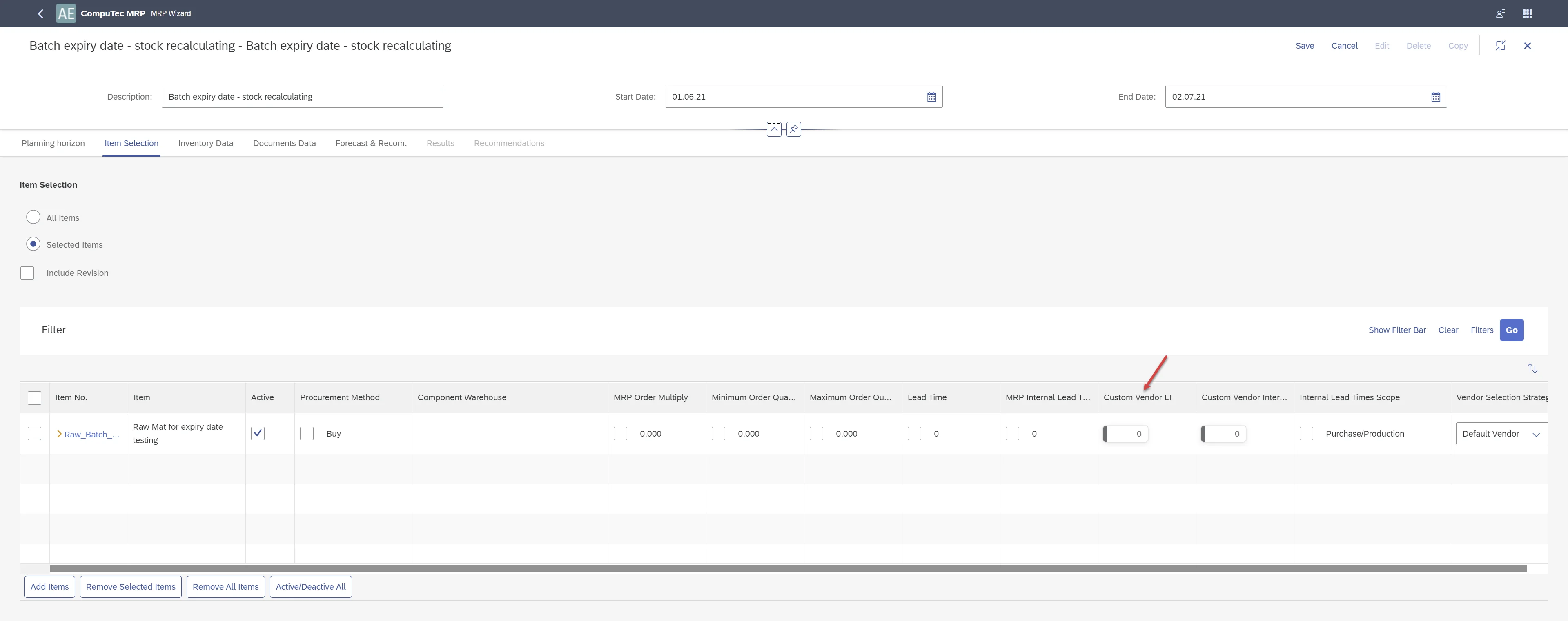

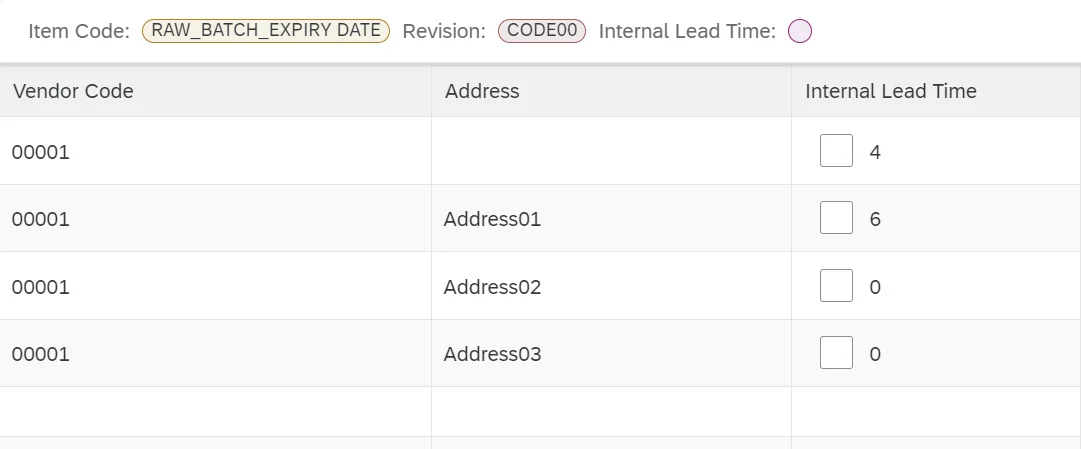

Based on the data defined in Business Partner Master Data, a set of rules is established for Internal Vendor Lead Time.

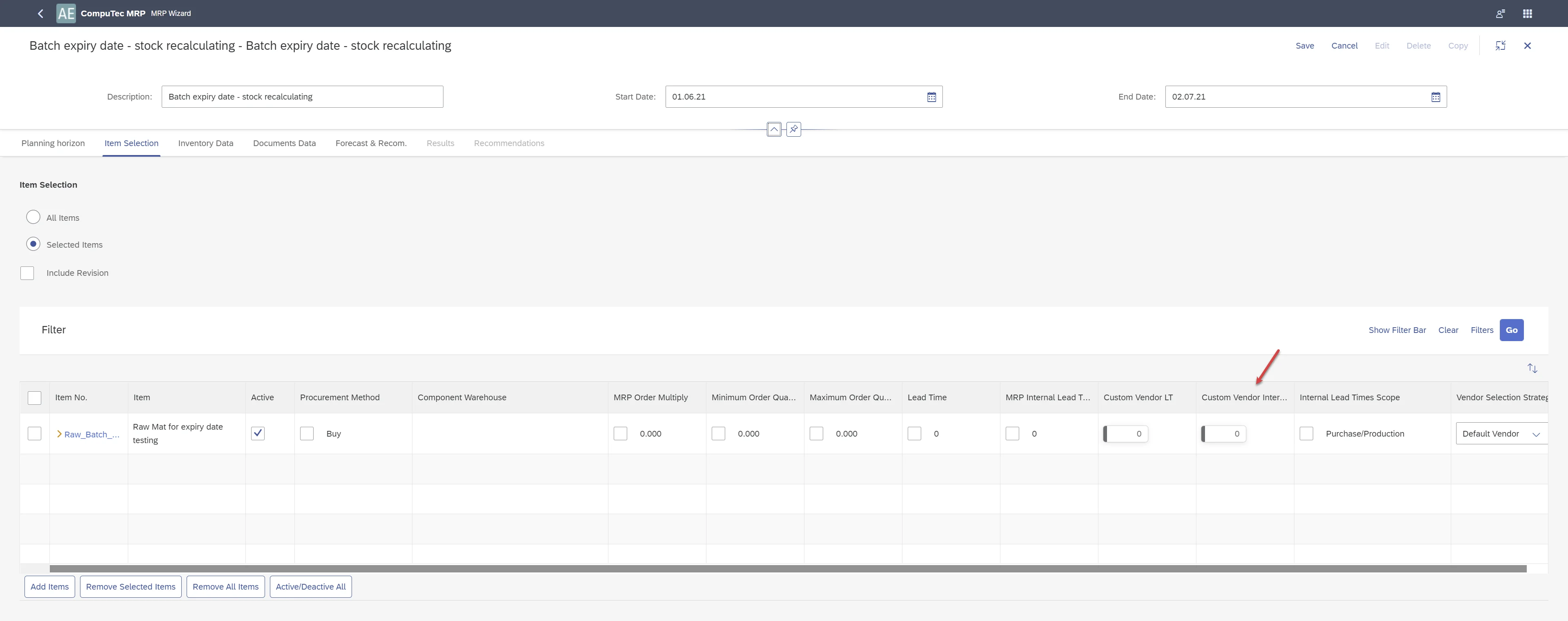

These rules can be accessed in the Item Selection tab under the Custom Vendor Internal Lead Time column. Here, you can modify Internal Lead Time values as needed. Any edited values are mandatory for the current scenario.

When preparing an MRP 2.5 recommendation, the system will identify the most appropriate rule where the Internal Lead Time is greater than zero. The selection process follows this priority:

- The system first searches for a rule that matches both the Vendor (default) and Shipping Address (default) as defined in the master data.

- If no valid Internal Lead Time > 0 is found for the Vendor (default) & Shipping Address (default) combination, the system will attempt to find a match based on the Vendor (default) alone.

- If no valid rule is found, the system will use the Internal Lead Time from Item Master Data (located under Item Details for review).