You are currently viewing documentation for CompuTec ProcessForce 3.0, which is a plugin installed and managed through CompuTec AppEngine 3.0, built on .NET 8.

If you are working with older environments, you may need the documentation for CompuTec ProcessForce 2.0, which is still supported: https://learn.computec.one/docs/processforce/2.0/.

Please note that CompuTec AppEngine 3.0 introduces a new architecture. All CompuTec components, including the CompuTec ProcessForce 3.0 plugin, must be updated together to ensure full compatibility.

Before starting your installation or upgrade process, we strongly recommend reviewing the CompuTec AppEngine 3.0 and CompuTec ProcessForce 3.0 documentation.

Defects

In quality control, identifying and managing defects is essential for maintaining high standards and ensuring product reliability. The Defects and Defect Groups setup allows users to efficiently record, categorize, and analyze defects that arise during quality testing. This setup not only enhances reporting accuracy but also streamlines quality assurance processes.

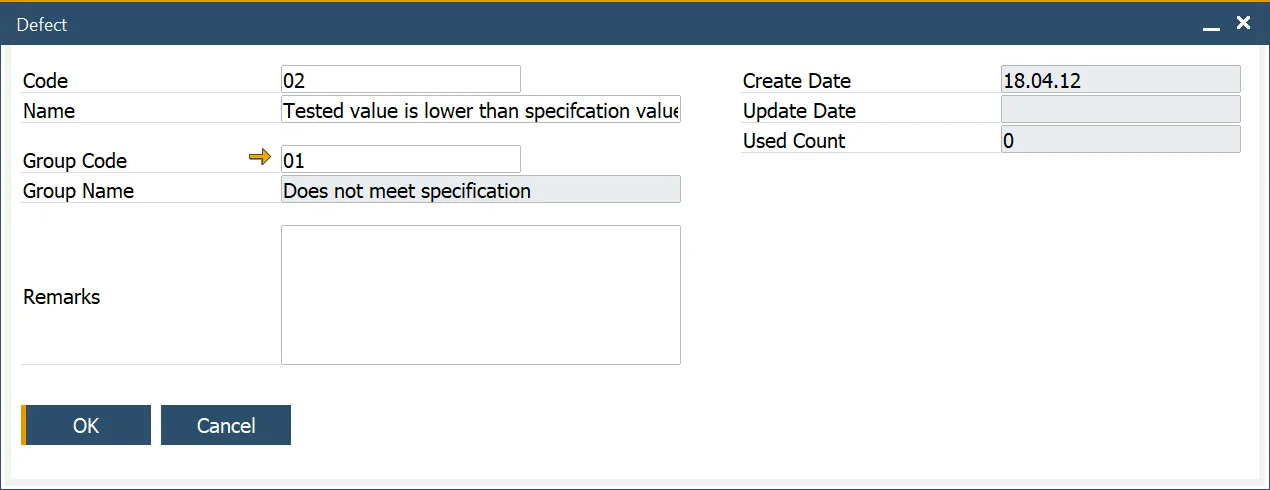

Defect

Administration → Setup → Quality Control → Defects

The Defects form enables users to define specific Defect Codes and associate them with a Group Code for streamlined reporting and detailed analysis. These codes are essential for documenting defects when an item fails quality tests.

Key features include:

- Defect Codes: Unique identifiers for recording specific defects.

- Group Code: Used to categorize defects for better organization.

- Used Count: Tracks the frequency of each Defect Code's usage, providing insights for quality improvement.

These Defect Codes are utilized within the Quality Control Test Form to log and monitor defective items effectively.

Defect Groups

Administration → Setup → Quality Control → Defect Groups

The Defect Groups form allows users to organize individual Defect Codes into broader categories. This grouping facilitates detailed reporting and analysis, enabling better insights into recurring quality issues and trends.