You are currently viewing documentation for CompuTec ProcessForce 3.0, which is a plugin installed and managed through CompuTec AppEngine 3.0, built on .NET 8.

If you are working with older environments, you may need the documentation for CompuTec ProcessForce 2.0, which is still supported: https://learn.computec.one/docs/processforce/2.0/.

Please note that CompuTec AppEngine 3.0 introduces a new architecture. All CompuTec components, including the CompuTec ProcessForce 3.0 plugin, must be updated together to ensure full compatibility.

Before starting your installation or upgrade process, we strongly recommend reviewing the CompuTec AppEngine 3.0 and CompuTec ProcessForce 3.0 documentation.

Manufacturing Orders Relations

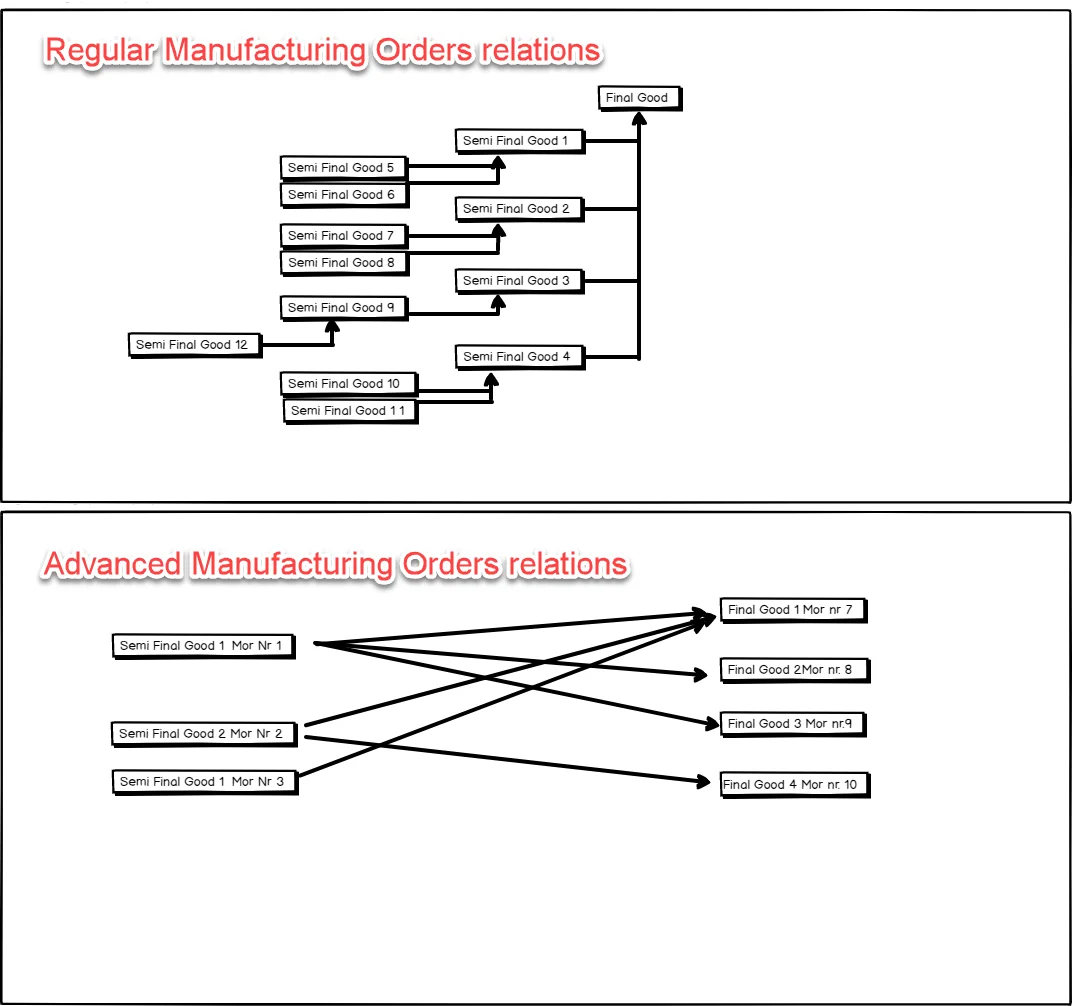

In a complex manufacturing environment, managing relationships between different Manufacturing Orders (MOs) is crucial for efficiency and traceability. The Manufacturing Orders Relations feature enables users to create advanced MO connections, linking a Child Manufacturing Order with multiple Parent Manufacturing Orders to streamline production workflows.

Purpose

This functionality provides a structured way to track and manage dependencies between MOs, ensuring smooth production planning and resource allocation.

Activating the Option

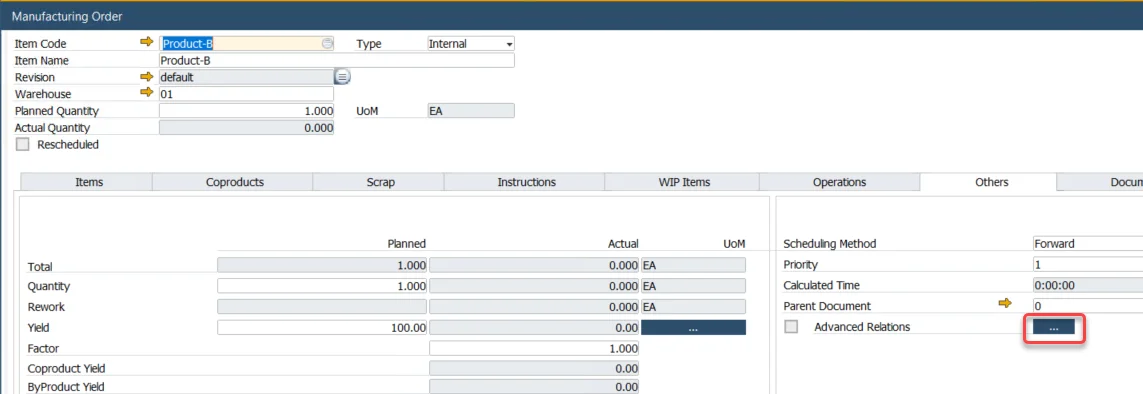

Production → Manufacturing Order → Manufacturing Order → Others tab

Click the highlighted button to open the Manufacturing Orders Relations form.

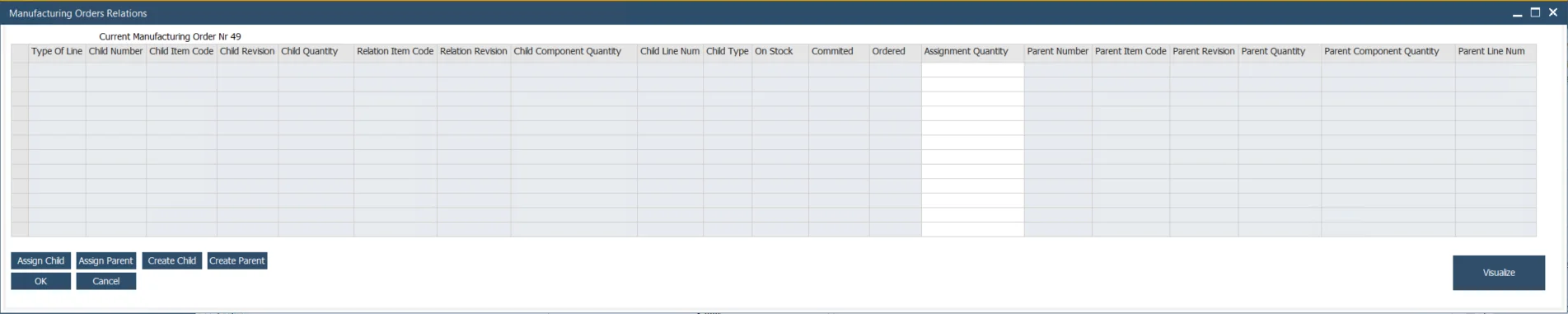

Manufacturing Orders Relations Form

Creating relation

Assigning Already Existing Manufacturing Orders

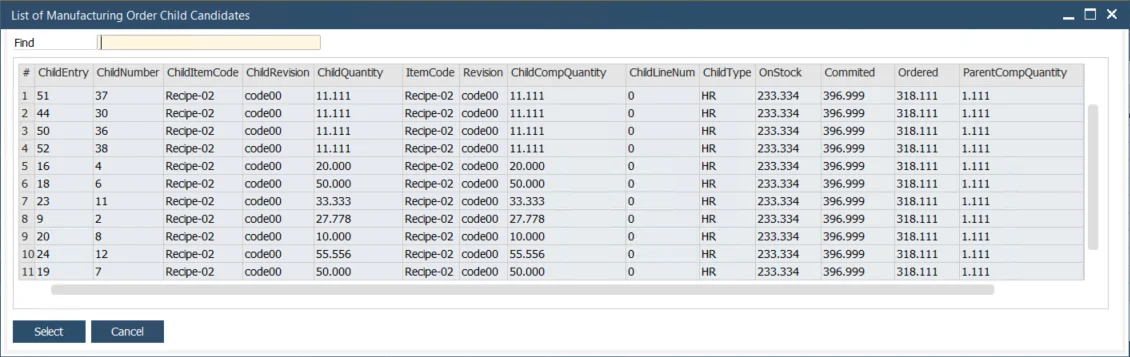

Assigning Child Manufacturing Orders

Clicking the "Assign Child" button displays a list of all MOs in Scheduled, Released, or Started status for an Item and Revision of a component in the selected MO. Users can choose one or more from the list and click Select to add them as child MOs.

Assigning Parent Manufacturing Orders

Clicking the "Assign Parent" button ahows a list of all Manufacturing Orders in Scheduled, Released, and Started status with a component of the chosen Manufacturing Order.

Creating new Manufacturing Orders

-

Creating new Child Manufacturing Order

Clicking Create Child opens a list of Bill of Materials (BOMs) matching the raw material of the chosen Manufacturing Order, allowing users to generate a new child order.

-

Creating New Parent Manufacturing Orders

Clicking the "Create Parent" button leads to a list of all Bill of Materials that have a component of the chosen Manufacturing Order.

Visualize

The Visualize option provides a clear scheme of MO connections, helping users understand dependencies and improve production planning.