You are currently viewing documentation for CompuTec ProcessForce 3.0, which is a plugin installed and managed through CompuTec AppEngine 3.0, built on .NET 8.

If you are working with older environments, you may need the documentation for CompuTec ProcessForce 2.0, which is still supported: https://learn.computec.one/docs/processforce/2.0/.

Please note that CompuTec AppEngine 3.0 introduces a new architecture. All CompuTec components, including the CompuTec ProcessForce 3.0 plugin, must be updated together to ensure full compatibility.

Before starting your installation or upgrade process, we strongly recommend reviewing the CompuTec AppEngine 3.0 and CompuTec ProcessForce 3.0 documentation.

Pick by Operation

Efficient inventory management is crucial in manufacturing, and the Pick by Operation function simplifies the process by ensuring materials are picked based on specific operations within a Manufacturing Order. This feature allows users to track picking status and optimize resource allocation.

Issue to Operation

-

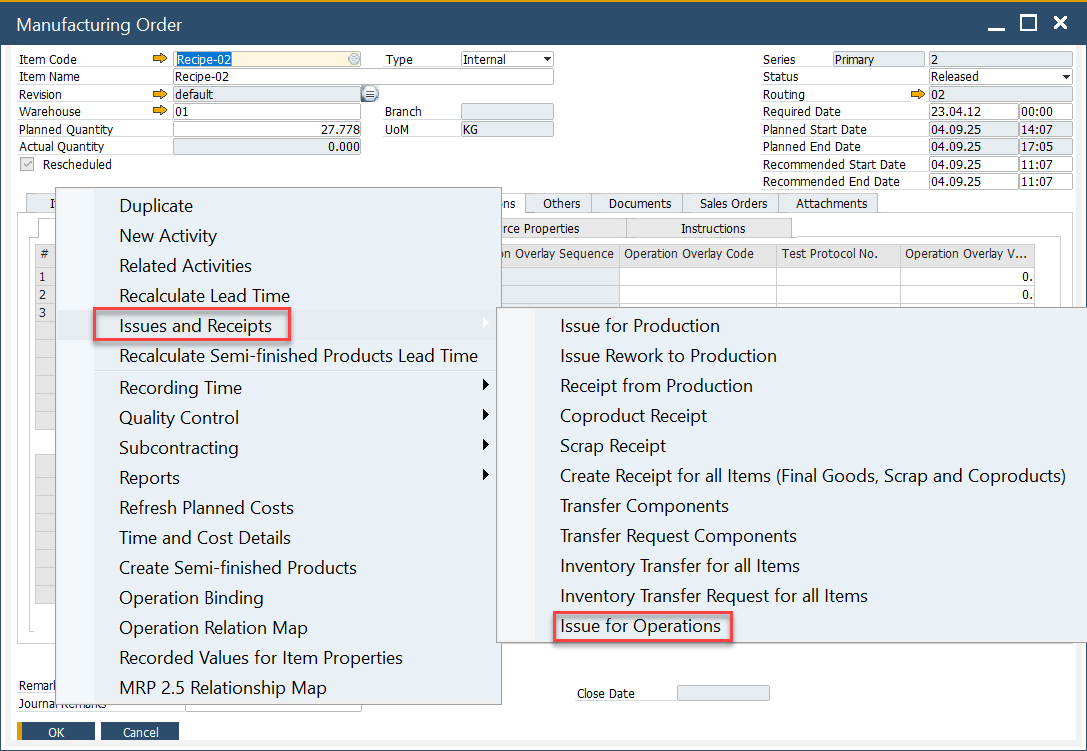

Open the Manufacturing Order and select Issue to Operations from the context menu.

-

This menu option will only be displayed if there is an Item linked to an Operation (you can check how to do this here).

-

If an Item is not linked to an Operation, this menu will not be displayed.

-

A List of Operations with linked Items will be displayed.

-

Select single or multiple rows

-

Note that the Operation Status is based on the Operations Tab and Time Bookings.

-

Pick Status displays the progress of Picking.

-

Valid values are:

- Not Picked

- Partially Picked (status changes when a Pick Issue has been created),

- Finished.

Pick Order

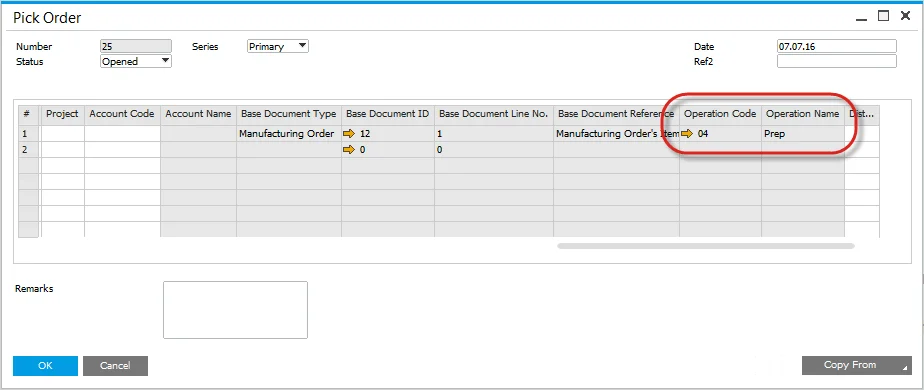

- The Pick Order Form will open, displaying items linked to the selected operation.

- The Operation Code and Name are recorded for reference.

- Proceed with the picking process as per standard procedures.

Pick Status

-

When a Pick Order is created and Items have been partially picked, the Picked Status will change to Picked.

-

Once all items are picked, the status changes to Finished.

Operation Picking Status

-

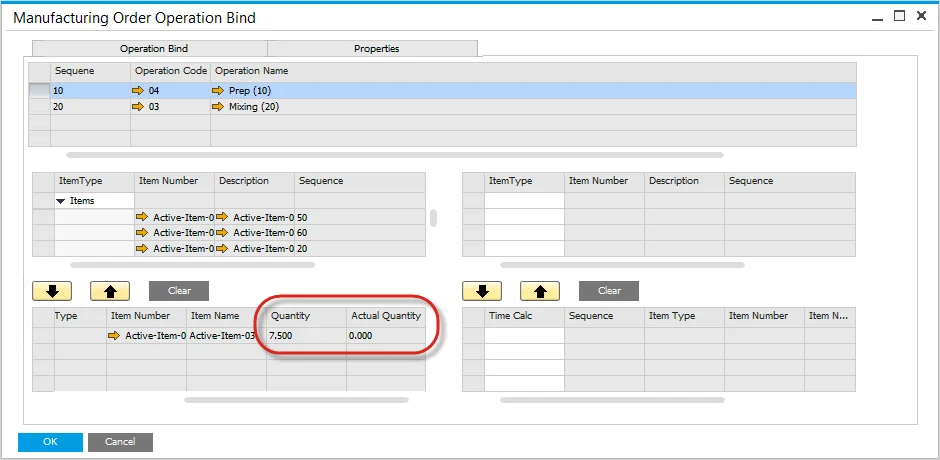

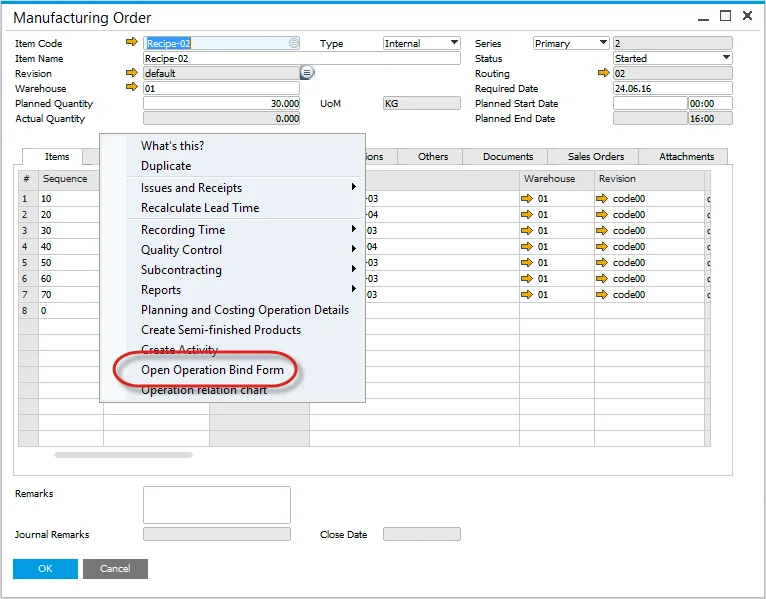

Open the Operation Bind Form to view a summary of the Operation Picking.

-

Planned and Actual Quantities are displayed.